Using a DTF Powder Printer efficiently can transform your printing business. This technology offers a cost-effective and versatile solution, allowing you to produce high-resolution prints on various surfaces. Efficiency directly impacts print quality and productivity, ensuring you meet customer demands swiftly. By focusing on key areas like equipment setup and maintenance, you can maximize the potential of your printer. Embrace this innovative method to stay competitive in the ever-evolving printing landscape, where speed and quality are paramount.

Key Takeaways

Maximize your DTF Powder Printer’s potential by ensuring proper setup and regular maintenance to achieve high-quality prints.

Utilize versatile DTF printing to create vibrant designs on various materials, expanding your product offerings and customer base.

Invest in quality equipment, including a compatible printer and high-grade DTF film and powder, to enhance print durability and clarity.

Follow a step-by-step printing process, from design preparation to heat pressing, to avoid common pitfalls and ensure successful transfers.

Implement regular cleaning and calibration routines to maintain printer performance and prevent costly repairs.

Leverage online communities and manufacturer resources for support, tips, and troubleshooting to enhance your printing experience.

Optimize your workflow by organizing your workspace and managing your time effectively to boost productivity and meet customer demands.

Understanding DTF Printing

What is DTF Printing?

DTF printing, or Direct-to-Film printing, is a cutting-edge technique that lets you transfer vibrant and intricate designs onto various materials. Unlike traditional methods, DTF printing uses a special film to print your design, which you then transfer onto fabric. This process involves a DTF Powder Printer, DTF film, and unique inks. You print the design on the film, apply adhesive powder, cure it, and finally press it onto the fabric using a heat press. This method opens up a world of possibilities for DIY enthusiasts and small businesses looking to create high-quality, durable prints.

Benefits of DTF Printing

Versatility in Design

One of the standout features of DTF printing is its versatility. You can print on a wide range of materials, not just fabrics. Whether it’s cotton, polyester, or even more challenging textiles, DTF printing handles them all with ease. This flexibility means you can customize almost any item, from t-shirts to tote bags, without being limited by the type of fabric. The ability to produce detailed and colorful designs makes DTF printing a favorite among those who want to push creative boundaries.

Cost-Effectiveness

DTF printing is not only versatile but also cost-effective. By eliminating the need for third-party printing services, you save money and gain complete control over your designs. This method allows you to print on demand, reducing waste and ensuring you only produce what you need. The initial investment in a DTF Powder Printer and supplies pays off quickly as you start creating and selling custom designs. This efficiency makes DTF printing an attractive option for businesses looking to maximize their profits while maintaining high-quality output.

How DTF Powder Printers Work

Understanding how a DTF Powder Printer operates is crucial for achieving the best results. These printers use advanced technology, combining specialty inks and sophisticated software to deliver precise and vibrant prints. The process begins with printing your design onto a special film. After printing, you apply an adhesive powder to the wet ink. This powder ensures the design adheres properly to the fabric during the heat press stage. The printer’s ability to handle intricate designs without needing separate layers for colors sets it apart from other printing methods. With the right setup and maintenance, your DTF printer will consistently produce stunning, long-lasting prints.

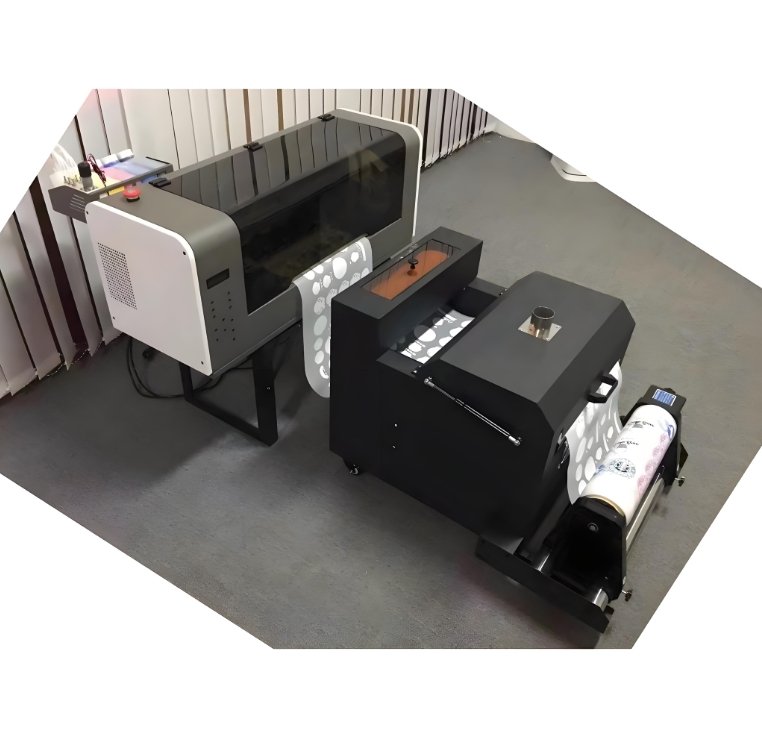

Essential Equipment and Setup

To get the most out of your DTF Powder Printer, you need the right equipment and a proper setup. This ensures that your prints come out looking sharp and vibrant every time. Let’s dive into what you’ll need and how to set it all up.

Required Equipment

Before you start printing, gather all the necessary tools. Here’s a quick rundown of what you’ll need:

Printer and Software

First, you need a printer that’s compatible with DTF ink. Look for one that includes CMYK and White ink channels, as these are essential for producing high-quality prints. Alongside the printer, you’ll need design software on your computer. This software helps you create or edit your designs before printing them onto the film. Popular choices include Adobe Photoshop or CorelDRAW, which offer robust features for design work.

DTF Film and Powder

Next, stock up on DTF film and powder. The film is where you’ll print your design, and the powder acts as an adhesive to transfer the design onto fabric. Make sure to choose high-quality film and powder to ensure the best results. The powder should be stored in a cool, dry place to maintain its effectiveness.

Setting Up Your Printer

Once you have all your equipment, it’s time to set up your printer. Proper setup is crucial for achieving peak efficiency and quality.

Initial Calibration

Start by calibrating your printer. This step ensures that the printer’s settings align with the specific requirements of DTF printing. Follow the manufacturer’s instructions to adjust the print head alignment and ink flow. Calibration helps prevent issues like blurry prints or color inconsistencies.

Software Configuration

After calibration, configure your design software. Set the correct resolution and color profiles to match your printer’s capabilities. This step is vital for maintaining color accuracy and detail in your prints. Make sure your software is updated to the latest version to take advantage of new features and improvements.

By ensuring you have the right equipment and a well-configured setup, you’ll be on your way to producing stunning prints with your DTF Powder Printer. This preparation sets the foundation for a smooth and efficient printing process.

Step-by-Step Guide to Using Your DTF Powder Printer

Preparing Your Design

Before you start printing, you need to prepare your design carefully. This step is crucial for achieving high-quality prints with your DTF Powder Printer.

Design Software Tips

To create your design, use graphic design software like Adobe Photoshop or Illustrator. These programs offer robust tools for crafting detailed and vibrant designs. Make sure your artwork is in CMYK color mode, which is ideal for printing. This ensures that the colors in your design match what your printer can produce. If you’re not creating your design from scratch, consider using pre-made designs from stock image websites or purchasing them from a graphic designer.

File Formats and Resolutions

Choosing the right file format and resolution is key to maintaining the quality of your prints. The best file formats for DTF printing are PNG and TIFF. These formats support high resolution and transparency, ensuring your design retains its detail when printed. Aim for a resolution of at least 300 dpi (dots per inch). This level of detail ensures that your prints are sharp and clear. Proper color management is also essential. Use a color profile that matches your printer and inks to achieve accurate and vibrant colors.

Printing Process

Once your design is ready, it’s time to move on to the printing process. This involves loading your materials and adjusting your printer settings for optimal results.

Loading Film and Powder

Start by loading the DTF film into your printer. Make sure the film is positioned correctly to avoid any misprints. Next, prepare the adhesive powder. This powder plays a crucial role in transferring your design onto fabric. Ensure the powder is stored in a cool, dry place to maintain its effectiveness. Apply the powder evenly over the wet ink on the film. This step is vital for ensuring the design adheres properly during the heat press stage.

Adjusting Printer Settings

Adjust your printer settings to match the requirements of your design. Set the correct resolution and color profiles in your design software. This ensures that the printed image is as close to your original design as possible. Check the ink levels and make sure the print head is clean to prevent any issues during printing. Regular maintenance of your DTF Powder Printer will help you achieve consistent and high-quality prints.

Transferring the Design

After printing, the next step is transferring your design onto the fabric. This involves using a heat press to ensure proper adhesion.

Heat Press Techniques

Using a heat press requires precision. Set the temperature and pressure according to the fabric type and the instructions provided with your DTF materials. A common practice is to maintain a gap of around 4 to 7 mm between the film and the heat press top plate. This ensures effective heat transfer without damaging the design or fabric. Follow the recommended pressing time to ensure the design adheres properly.

Ensuring Proper Adhesion

Proper adhesion is crucial for the durability of your prints. After pressing, allow the fabric to cool before peeling off the film. This helps the design set firmly onto the fabric. If you notice any areas where the design hasn’t adhered properly, you can re-press those sections. This step ensures that your prints are long-lasting and can withstand regular use.

By following these steps, you can make the most of your DTF Powder Printer and produce stunning, high-quality prints. With careful preparation and attention to detail, you’ll achieve professional results every time.

Maintenance for Long-Term Efficiency

Keeping your DTF Powder Printer in top shape is crucial for maintaining high-quality prints and extending the life of your equipment. Regular maintenance not only ensures consistent performance but also helps you avoid costly repairs down the line. Let’s dive into some essential maintenance practices that will keep your printer running smoothly.

Regular Cleaning and Upkeep

Regular cleaning is a must to prevent clogs and maintain print quality. Here’s how you can keep your printer in excellent condition:

Cleaning the Print Heads

Print heads are the heart of your printer. To keep them functioning properly, clean them regularly. Use a lint-free cloth and a gentle cleaning solution recommended by your printer’s manufacturer. Avoid harsh chemicals that might damage the delicate components. If your printer has an automatic cleaning function, use it as part of your routine. This helps prevent ink buildup and ensures smooth ink flow.

Maintaining the Powder System

The powder system plays a vital role in transferring designs onto fabric. Keep the powder system clean and free from clogs. Regularly check for any powder residue that might accumulate and affect performance. Store your adhesive powder in a cool, dry place to maintain its effectiveness. This simple step can make a big difference in the quality of your prints.

Software Updates and Calibration

Keeping your printer’s software up to date is just as important as physical maintenance. Software updates can enhance performance and fix bugs that might affect your printing process.

Importance of Firmware Updates

Firmware updates are crucial for your printer’s efficiency. They often include improvements that optimize performance and extend the printer’s lifespan. Regularly check for updates from the manufacturer. Before updating, back up your settings to avoid losing any custom configurations. Testing updates on a secondary system can help you ensure compatibility without disrupting your workflow.

Routine Calibration Checks

Calibration ensures that your printer produces accurate and vibrant prints. Perform routine calibration checks to align the print heads and adjust color profiles. Follow the manufacturer’s guidelines for calibration procedures. Regular checks help you catch any issues early and maintain consistent print quality.

By incorporating these maintenance practices into your routine, you’ll ensure that your DTF Powder Printer operates at peak efficiency. Regular cleaning, software updates, and calibration checks will keep your printer in excellent condition, allowing you to produce stunning prints every time.

Troubleshooting Common Issues

Even with the best setup and maintenance, you might encounter some hiccups with your DTF Powder Printer. Don’t worry—most issues have straightforward solutions. Let’s dive into some common problems and how you can tackle them.

Print Quality Problems

Blurry or Faded Prints

Blurry or faded prints can be frustrating, but you can often fix them with a few adjustments. First, check if you’re using the correct side of the DTF film. Printing on the wrong side can lead to poor results. Also, ensure you’re using the right type of DTF ink. If your prints still look off, try increasing the color percentage in your RIP settings. This adjustment helps the ink adhere better to the powder. Running a nozzle check can also reveal if any print heads are clogged, which might cause blurry prints.

Inconsistent Color Output

Inconsistent colors can ruin a design. Start by verifying that your ink tanks are at the same level as the print head. If they’re too high, it might cause ink flow issues. Ensure your printer’s color profiles match your design software settings. Sometimes, a delaminated print head can cause color inconsistencies. You can remove the print head and perform a “waterfall” test to check for this issue. If ink leaks from the side, the print head might need replacing.

Mechanical and Software Issues

Paper Jams and Misfeeds

Paper jams and misfeeds can disrupt your workflow. To prevent these, make sure the DTF film is loaded correctly. Check for any obstructions in the paper path and clear them. Regularly clean the rollers to ensure smooth feeding. If jams persist, inspect the film for any tears or damage that might cause feeding issues.

Software Errors and Fixes

Software errors can be a headache, but they’re usually easy to fix. Keep your printer’s firmware and design software updated to avoid compatibility issues. If you encounter an error, restarting your software or computer can often resolve it. Double-check your settings to ensure they’re configured correctly for DTF printing. If problems persist, consult your printer’s manual or reach out to the manufacturer’s support for guidance.

By addressing these common issues, you’ll keep your DTF Powder Printer running smoothly. Regular checks and adjustments will help you maintain high-quality prints and minimize downtime. Remember, a little troubleshooting goes a long way in ensuring your printer’s peak performance.

Final Tips for Maximizing Efficiency

Maximizing efficiency with your DTF Powder Printer involves more than just having the right equipment. It requires adopting best practices and leveraging available resources to streamline your workflow and enhance productivity. Here are some final tips to help you get the most out of your printer.

Best Practices for Daily Use

Efficient Workflow Tips

Creating an efficient workflow is essential for maximizing productivity. Start by organizing your workspace to minimize clutter and ensure easy access to all necessary materials. Arrange your printer, film, and powder in a logical sequence to streamline the printing process. Consider investing in reliable production management software. This tool can help you manage your printing tasks, track inventory, and provide real-time insights into your operations. By optimizing your workflow, you can reduce downtime and increase output.

Time Management Strategies

Effective time management is crucial for maintaining efficiency. Set specific goals for each printing session and allocate time for each task. Prioritize urgent orders and plan your schedule to accommodate them. Use timers or alarms to keep track of your progress and ensure you stay on track. Regularly review your processes to identify areas where you can save time. By managing your time wisely, you can meet deadlines and improve customer satisfaction.

Leveraging Community and Resources

Online Forums and Groups

Joining online forums and groups can be incredibly beneficial. These communities offer a wealth of knowledge and support from fellow DTF printing enthusiasts. You can share experiences, ask questions, and learn from others who have faced similar challenges. Participating in these groups can provide you with valuable tips and tricks to enhance your printing process. Plus, it’s a great way to stay updated on the latest trends and innovations in the industry.

Manufacturer Support and Guides

Don’t overlook the resources provided by your printer’s manufacturer. Many manufacturers offer detailed guides and support services to help you get the most out of your DTF Powder Printer. Take advantage of these resources to troubleshoot issues, learn about new features, and optimize your printer’s performance. If you encounter any problems, reach out to the manufacturer’s support team for assistance. They can provide expert advice and solutions tailored to your specific needs.

By implementing these tips and leveraging available resources, you can maximize the efficiency of your DTF Powder Printer. Whether it’s through improving your workflow, managing your time effectively, or tapping into community knowledge, these strategies will help you achieve outstanding results and keep your printing business thriving.

Efficient use of your DTF Powder Printer is crucial for achieving top-notch results. By focusing on proper setup, operation, and maintenance, you ensure your prints are vibrant and durable. Remember to gather all essential materials like DTF film, powder, and a heat press. Follow the step-by-step process to avoid common pitfalls and enhance your printing experience. Implementing these tips will not only improve your workflow but also boost your productivity. Embrace these strategies to make the most of your printer and keep your business thriving.

FAQ

What is DTF printing?

DTF printing, or Direct-to-Film printing, is a modern technique that allows you to transfer vibrant designs onto various materials. You print your design on a special film, apply adhesive powder, and then use a heat press to transfer it onto fabric. This method is popular for its versatility and high-quality results.

Which printers can be used for DTF printing?

You can use printers that support DTF ink and have CMYK and White ink channels. These printers are specifically designed to handle the unique requirements of DTF printing, ensuring you get the best quality prints.

How do I maintain my DTF Powder Printer?

Regular maintenance is key. Clean the print heads frequently to prevent clogs. Store your adhesive powder in a cool, dry place. Keep your printer’s software updated and perform routine calibration checks to ensure optimal performance.

What materials can I print on with DTF?

DTF printing is incredibly versatile. You can print on a wide range of materials, including cotton, polyester, and even more challenging textiles. This flexibility allows you to customize items like t-shirts, tote bags, and more.

How do I ensure proper adhesion of my prints?

Use a heat press with the correct temperature and pressure settings for your fabric type. Maintain a gap of around 4 to 7 mm between the film and the heat press top plate. Allow the fabric to cool before peeling off the film to ensure the design sets firmly.

What file formats are best for DTF printing?

The best file formats for DTF printing are PNG and TIFF. These formats support high resolution and transparency, ensuring your design retains its detail when printed. Aim for a resolution of at least 300 dpi for sharp and clear prints.

How can I troubleshoot blurry or faded prints?

First, check if you’re using the correct side of the DTF film. Ensure you’re using the right type of DTF ink. Increase the color percentage in your RIP settings if needed. Run a nozzle check to see if any print heads are clogged.

What should I do if I encounter software errors?

Keep your printer’s firmware and design software updated. Restart your software or computer if you encounter an error. Double-check your settings to ensure they’re configured correctly for DTF printing. If problems persist, consult your printer’s manual or reach out to the manufacturer’s support.

How can I maximize the efficiency of my DTF Powder Printer?

Organize your workspace to minimize clutter. Use reliable production management software to manage tasks and track inventory. Set specific goals for each printing session and allocate time for each task. Join online forums and groups for tips and support from fellow DTF printing enthusiasts.

Where can I find support and resources for DTF printing?

Join online forums and groups dedicated to DTF printing. These communities offer valuable knowledge and support. Also, take advantage of resources provided by your printer’s manufacturer, including detailed guides and support services. Reach out to the manufacturer’s support team for expert advice tailored to your needs.