Why are the DTF powder benefits a game-changer for small printing shops? Well, it offers a host of advantages that can transform your business. First off, DTF supplies are incredibly cost-effective. You can enjoy up to 30% lower production costs for small orders compared to other methods. This means you can take on smaller jobs without worrying about high setup costs. Plus, DTF supplies allow you to produce vibrant and durable prints on various fabrics. This versatility ensures you meet diverse customer needs. With DTF, you get quality, affordability, and flexibility all in one package, thanks to the significant DTF powder benefits.

Key Takeaways

DTF powder significantly reduces production costs by up to 30% for small orders, making it a cost-effective choice for small printing shops.

This printing method allows for vibrant and durable prints on various fabrics, catering to diverse customer needs and preferences.

DTF printing supports low minimum order quantities, enabling shops to take on custom jobs without the financial burden of traditional methods.

Investing in quality DTF equipment and training staff effectively ensures high-quality output and operational efficiency.

Embracing DTF technology positions your business to adapt to market trends and expand service offerings, tapping into the growing demand for custom prints.

DTF printing is ideal for niche markets, allowing businesses to provide personalized solutions that enhance customer satisfaction and loyalty.

Understanding DTF Powder Benefits

What is DTF Powder?

DTF powder is a key component in the world of dtf printing. It’s made from high-purity polyurethane, which ensures that your prints stick well to the fabric. This powder acts as an adhesive, bonding the ink to the material. You sprinkle it over the printed design on a DTF film before curing. This step is crucial because it ensures the ink adheres properly, resulting in vibrant and durable prints. The powder works with all DTF printers, making it versatile for various fabrics like cotton and polyester. Choosing the right DTF powder for your fabric type is essential. Different powders suit different materials, so consider the fabric’s texture and weave to get the best results.

How Does DTF Powder Work?

The dtf process involves several steps, and DTF powder plays a vital role. After printing your design onto a DTF film, you apply the powder evenly over the wet ink. This powder acts as a hot melt adhesive, which means it melts when heated, bonding the ink to the fabric. Once you’ve applied the powder, you cure the print using a heat press. This step solidifies the bond, ensuring the print is durable and long-lasting. The powder’s adhesive properties make it possible to achieve high-quality prints that can withstand washing and wear. It’s important to operate in a well-ventilated area and use protective gear, as inhaling the powder can be harmful.

Why Small Printing Shops Need to Consider DTF Powder

For small printing shops, the dtf powder benefits are significant. First, it allows you to produce high-quality prints without the need for large-scale equipment. This means you can offer custom prints with low minimum order quantities, catering to niche markets and small custom jobs. The dtf supplies are cost-effective, reducing production costs by up to 30% for small orders compared to traditional methods. This affordability makes it easier for you to take on smaller jobs without worrying about high setup costs. Additionally, the versatility of DTF printing means you can work with a variety of fabrics, meeting diverse customer needs. With DTF, you gain the ability to deliver vibrant, durable prints that keep your customers coming back.

Cost-Effectiveness of DTF

When you’re running a small printing shop, keeping costs down is crucial. That’s where DTF printing comes in. It offers a cost-effective solution that can transform your business operations. Let’s dive into why DTF is a smart choice for your shop.

Low Minimum Order Quantities

One of the standout features of DTF printing is its ability to handle low-volume orders efficiently. Unlike traditional methods, which often require large minimum orders, DTF allows you to take on smaller jobs without breaking the bank. This flexibility means you can cater to niche markets and custom requests with ease. You won’t need to worry about excessive inventory or wasted resources. Instead, you can focus on delivering quality prints that meet your customers’ specific needs.

Affordable Setup Costs

Setting up a DTF printing operation doesn’t require a massive investment. The initial costs are significantly lower compared to other printing methods. You don’t need to invest in expensive screens or plates, as you would with screen printing. DTF supplies are more affordable, making it easier for you to get started. Plus, the digital nature of DTF printing reduces labor costs. You can produce high-quality prints with minimal manual intervention, saving both time and money.

Comparative Data:

DTF vs. Screen Printing: DTF eliminates the need for separate screens for each color, making it more cost-effective for smaller print runs.

DTF vs. DTG Printing: While DTG might be faster, DTF offers advantages in quality and durability, especially for low-volume orders.

By choosing DTF printing, you gain a competitive edge. You can offer your customers vibrant, durable prints without the hefty price tag. This approach not only boosts your profit margins but also enhances customer satisfaction. With DTF, you get the best of both worlds: affordability and quality.

Looking for high-quality DTF powder? Contact us now to get started with your printing business upgrade!

Quality and Customization with DTF Transfers

When it comes to dtf transfers, you can expect nothing less than top-notch quality. This printing method stands out for its ability to produce vibrant and detailed designs. The quality and durability of dtf transfers make them a preferred choice for many small printing shops. You get prints that not only look great but also last long, even after multiple washes. The Transfer Express Team, known for their expertise in dtf transfers, emphasizes the importance of quality. They have spent years perfecting their products to ensure that every transfer leaving their shop meets high standards.

High-Quality Output

With dtf, you achieve high-quality output that rivals traditional printing methods. The process ensures that every detail of your design is captured with precision. Whether you’re printing a simple logo or a complex graphic, dtf transfers deliver sharp and vibrant results. This quality is crucial for custom apparel printing, where every detail matters. You want your customers to be impressed with the final product, and dtf helps you achieve that.

Versatility Across Fabric Types

One of the standout features of dtf transfers is their versatility. You can use them on a wide range of fabrics, from cotton to polyester. This flexibility allows you to cater to different customer needs without worrying about compatibility issues. Whether you’re working on t-shirts, hoodies, or tote bags, dtf has got you covered. This versatility is a game-changer for small printing shops looking to expand their offerings.

Streamlined Process and Ease of Use

The dtf process is straightforward and user-friendly. You don’t need extensive training to get started, making it ideal for small shops with limited resources. The steps are simple: print your design, apply the powder, and cure it with a heat press. This streamlined process saves you time and effort, allowing you to focus on what matters most—delivering quality prints to your customers. Plus, the ease of use means you can quickly adapt to new projects and meet tight deadlines.

By embracing dtf transfers, you enhance your shop’s capabilities. You offer high-quality, customizable prints that meet diverse customer demands. The combination of quality, versatility, and ease of use makes dtf an essential tool for any small printing business.

High Profit Margins from Custom Prints

When you dive into the world of dtf transfers, you’re not just exploring a printing method; you’re unlocking a treasure trove of profit potential. The beauty of dtf transfers lies in their ability to deliver high-quality, custom prints that command premium prices. This means you can significantly boost your profit margins while keeping your customers delighted with unique and personalized products.

Customization at Its Best: With dtf transfers, you can offer a wide range of custom designs that cater to individual tastes and preferences. Whether it’s a one-off design for a special event or a series of prints for a niche market, the possibilities are endless. This level of customization allows you to charge more for your services, as customers are often willing to pay a premium for personalized items.

Efficient Production Process: The dtf process is streamlined and efficient, allowing you to produce high-quality prints quickly and with minimal waste. This efficiency translates into lower production costs, which means more money in your pocket. You can take on more orders without the need for additional resources, maximizing your output and profitability.

Durability Equals Value: Customers value products that last, and dtf transfers excel in this area. The prints are not only vibrant but also durable, withstanding multiple washes without fading. This durability enhances the perceived value of your products, enabling you to justify higher prices and increase your profit margins.

Expert Insights: According to the Transfer Express Team, years of research and development have gone into perfecting dtf transfers. Their commitment to quality ensures that every transfer meets high standards, providing you with reliable products that your customers will love.

Market Demand: The demand for custom prints is on the rise, and dtf transfers position you perfectly to tap into this growing market. By offering unique and high-quality products, you can attract a loyal customer base willing to pay for the exclusivity and quality that dtf transfers provide.

Incorporating dtf transfers into your business strategy not only enhances your product offerings but also significantly boosts your bottom line. By focusing on customization, efficiency, and quality, you can enjoy high profit margins and a thriving business.

Comparing DTF with Traditional Printing Methods

When you’re considering different printing methods for your shop, it’s crucial to understand how DTF stacks up against traditional options. Let’s dive into the specifics of how DTF compares to screen printing and DTG (Direct-to-Garment) printing.

DTF vs. Screen Printing

Screen printing has been a staple in the printing industry for years. It’s known for producing vibrant colors and durable prints. However, it comes with its own set of challenges. You need to create separate screens for each color in your design, which can be time-consuming and costly. This method also requires significant manual labor and long setup times, making it less ideal for small orders or custom jobs.

On the other hand, DTF offers a more streamlined process. You don’t need to worry about creating multiple screens. Instead, you print your design directly onto a film, apply the DTF powder, and then transfer it to the fabric. This method saves you time and reduces labor costs. Plus, DTF allows you to handle low-volume orders efficiently, making it perfect for custom prints and niche markets.

Brandon Mills, a business owner who explored various printing methods, found DTF to be a game-changer. He initially tried screen printing but faced limitations due to its manual nature and setup requirements. By switching to DTF, he transformed his company into a leader in the industry, offering both apparel and transfer services.

DTF vs. DTG (Direct-to-Garment) Printing

DTG printing is another popular method, especially for printing on cotton garments. It allows you to print directly onto the fabric, which can be faster than other methods. However, DTG requires pre-treating the garments, adding an extra step to the process. This can be a hassle, especially if you’re dealing with a variety of fabric types.

DTF, in contrast, offers more versatility. You can use it on a wide range of fabrics, from cotton to polyester, without the need for pre-treatment. This flexibility means you can cater to diverse customer needs without worrying about compatibility issues. Additionally, DTF provides high-quality prints that are both vibrant and durable, ensuring customer satisfaction.

For small businesses and local print shops, understanding the benefits of DTF can help you make informed decisions. By choosing DTF, you gain flexibility, quality, and profitability, allowing you to scale and improve your custom apparel services.

Practical Tips for Implementing DTF

Implementing DTF printing in your shop can be a game-changer. To make the most of it, you need to focus on two key areas: choosing the right equipment and training your staff effectively. Let’s dive into these practical tips to ensure a smooth transition.

Choosing the Right Equipment

Selecting the right equipment is crucial for successful DTF printing. You want to invest in machines that suit your shop’s needs and budget. Here’s what to consider:

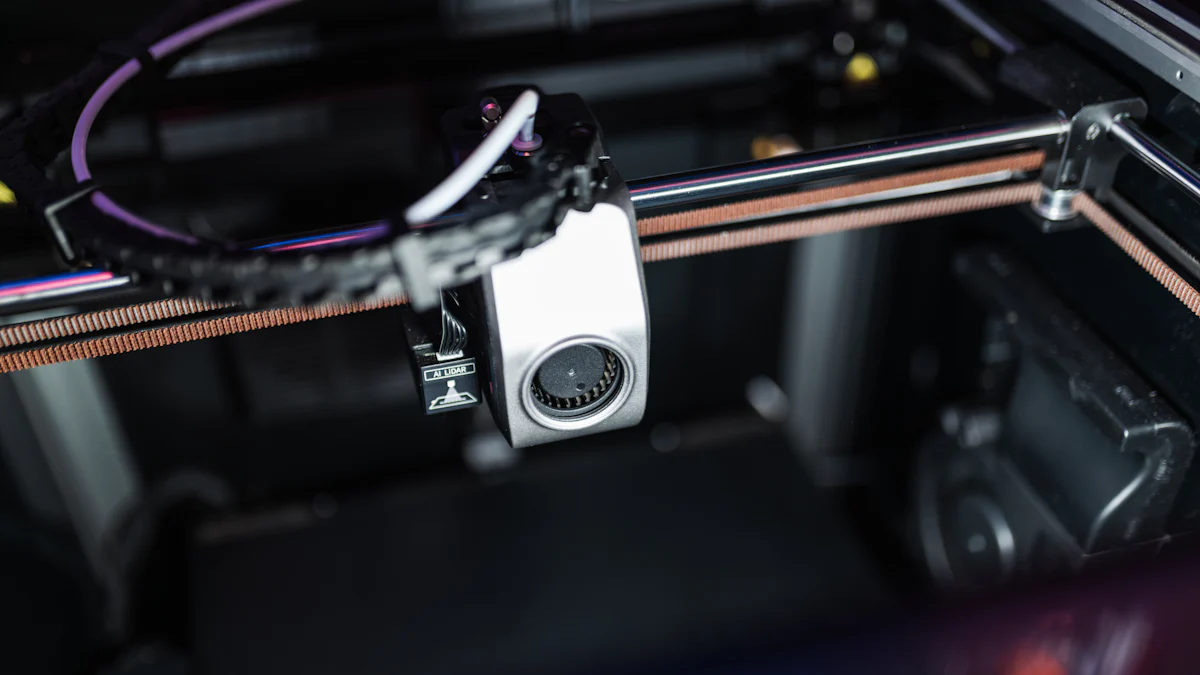

Printer Compatibility: Ensure your printer is compatible with DTF technology. Look for models specifically designed for DTF printing to avoid compatibility issues.

Heat Press: A reliable heat press is essential. It helps cure the prints and ensures the powder adheres properly. Choose one with adjustable temperature and pressure settings for versatility.

Powder Applicator: While you can apply powder manually, an automatic applicator can save time and improve consistency. It ensures even distribution, which is vital for high-quality prints.

Film Quality: Invest in high-quality DTF film. It affects the final print quality and durability. Look for films that work well with your chosen printer and powder.

By carefully selecting your equipment, you set the foundation for efficient and high-quality DTF printing. This investment pays off in the long run with satisfied customers and increased profits.

Training Staff for Optimal Use

Once you have the right equipment, training your staff becomes the next priority. Proper training ensures your team can operate the machines efficiently and produce top-notch prints. Here are some tips:

Hands-On Training: Provide hands-on training sessions. Let your staff practice with the equipment under supervision. This approach helps them gain confidence and understand the process better.

Step-by-Step Guides: Create easy-to-follow guides for each step of the DTF process. Include troubleshooting tips for common issues. These guides serve as handy references for your team.

Safety Protocols: Emphasize safety protocols. Ensure your staff knows how to handle the powder safely and operate the machines without risk. Safety should always be a top priority.

Continuous Learning: Encourage continuous learning. Keep your team updated with the latest DTF techniques and trends. Attend workshops or webinars together to stay ahead in the industry.

Training your staff effectively not only boosts productivity but also enhances the quality of your prints. A well-trained team can adapt quickly to new projects and meet customer demands efficiently.

By focusing on the right equipment and thorough training, you can seamlessly integrate DTF printing into your shop. This approach ensures you deliver high-quality, customized prints that keep your customers coming back for more.

Addressing Common Challenges with DTF

When you dive into the world of DTF printing, you might encounter a few bumps along the way. But don’t worry! With a little guidance, you can navigate these challenges smoothly and make the most of your DTF transfers.

Managing Initial Costs

Starting with DTF printing doesn’t have to break the bank. You can find affordable equipment solutions, especially from manufacturers in China. These options have driven market growth and made DTF more accessible. However, it’s crucial to balance cost with quality. Quality-conscious clients often prefer working with reputable DTF printer manufacturers. Investing in reliable equipment might seem costly upfront, but it pays off in the long run with fewer maintenance issues and better print quality.

Consider the usage and fabric type when selecting DTF powder. This choice affects both cost and shelf life. By making informed decisions, you can manage initial costs effectively and set your business up for success.

Ensuring Consistent Quality

Achieving consistent quality with DTF transfers requires attention to detail. Start by understanding the DTF process thoroughly. Optimal heat press settings play a vital role in ensuring that your prints come out vibrant and durable. Regularly maintain your equipment to prevent any hiccups in the printing process.

Training your staff is equally important. A well-trained team can handle the equipment efficiently and troubleshoot common issues. Encourage continuous learning and keep your team updated with the latest DTF techniques. This approach ensures that every print meets high standards, keeping your customers satisfied and coming back for more.

Clogging Issues and How to Avoid Them

Clogging can be a pesky problem in DTF printing, but you can avoid it with proper care. Regular maintenance of your printer is key. Clean the print heads frequently to prevent ink buildup, which can lead to clogs. Using high-quality DTF powder and film also helps reduce the risk of clogging.

Ensure that your workspace is clean and free from dust, as particles can interfere with the printing process. Additionally, store your DTF supplies properly to maintain their quality. By taking these preventive measures, you can minimize clogging issues and keep your DTF transfers running smoothly.

By addressing these common challenges head-on, you can make the most of DTF printing. With careful planning and attention to detail, you’ll deliver high-quality, cost-effective prints that delight your customers.

Managing Powder Application and Adhesion Issues

When working with DTF transfers, getting the powder application just right is crucial. You want your prints to stick well and last long. Here’s how you can manage this effectively:

Even Application: Make sure you apply the DTF powder evenly over your printed design. Uneven application can lead to poor adhesion and patchy prints. Use a powder applicator if possible. It helps distribute the powder uniformly, ensuring every part of your design gets the adhesive it needs.

Optimal Heat Settings: The heat press settings play a big role in how well the powder adheres. Set your heat press to the recommended temperature and pressure for the fabric you’re using. This ensures the powder melts properly and bonds the ink to the fabric.

Quality Materials: Always choose high-quality DTF powder and film. These materials affect the final print quality and durability. Investing in good supplies might cost more upfront, but it saves you from dealing with adhesion issues later.

Regular Maintenance: Keep your equipment clean and well-maintained. Dust and debris can interfere with the powder application process. Regular cleaning ensures your prints come out perfect every time.

By focusing on these aspects, you can ensure your DTF transfers adhere well and produce vibrant, long-lasting prints.

Handling Environmental and Health Concerns

Using DTF transfers involves handling materials that require careful attention to environmental and health concerns. Here’s how you can manage these responsibly:

Ventilation: Ensure your workspace is well-ventilated. The process of applying and curing DTF powder can release fumes. Good ventilation helps keep the air clean and safe for you and your team.

Protective Gear: Always wear protective gear when handling DTF materials. Gloves and masks protect you from inhaling powder particles or coming into direct contact with chemicals.

Eco-Friendly Options: Consider using eco-friendly DTF powders and films. Many suppliers offer options that are less harmful to the environment. These materials can be a great selling point for eco-conscious customers.

Proper Disposal: Dispose of any waste materials properly. Follow local regulations for disposing of chemical waste to minimize environmental impact.

By taking these steps, you not only protect yourself and your team but also contribute to a healthier environment. This approach ensures that your DTF transfers are not only high-quality but also responsibly produced.

Future-Proofing Your Business with DTF

In the ever-evolving world of printing, staying ahead of the curve is crucial. DTF offers a fantastic way to future-proof your business. Let’s explore how you can adapt to market trends, expand your service offerings, and tap into the booming print-on-demand services.

Adapting to Market Trends

Keeping up with market trends can feel like a full-time job. But with DTF, you’re already a step ahead. This technology allows you to produce vibrant and durable prints that meet the demands of today’s consumers. People want unique, high-quality products, and DTF delivers just that. By staying informed about the latest trends in fashion and design, you can use DTF printing to create products that resonate with your audience. Whether it’s the latest color palette or a trending graphic style, DTF gives you the flexibility to adapt quickly.

Expanding Service Offerings

Diversifying your services is a smart move for any business. With DTF, you can easily expand what you offer. Think beyond t-shirts. Consider tote bags, hats, and even home decor items. The versatility of DTF printing means you can cater to a wide range of customer needs. Offering more products not only attracts new customers but also keeps your existing ones coming back for more. Plus, with small-batch production, you can test new ideas without a huge upfront investment. This approach minimizes risk while maximizing potential rewards.

Ideal for Print-on-Demand Services

Print-on-demand is booming, and DTF fits perfectly into this model. Customers love the idea of getting custom products without long wait times. With DTF, you can offer quick turnaround times and high-quality prints. This makes it ideal for businesses looking to tap into the print-on-demand market. You don’t need to hold large inventories, which reduces costs and waste. Instead, you print items as orders come in, ensuring each product is fresh and tailored to the customer’s specifications. This flexibility not only enhances customer satisfaction but also boosts your bottom line.

By embracing DTF, you’re not just keeping up with the competition—you’re setting the pace. This technology equips you to adapt, expand, and thrive in a dynamic market. So, gear up and let DTF take your business to new heights.

Catering to Niche Markets and Small Custom Jobs

In the world of printing, niche markets and small custom jobs offer a treasure trove of opportunities. With DTF printing, you can tap into these specialized areas and provide unique solutions that cater to specific customer needs. Let’s explore how you can make the most of these opportunities.

Identify Your Niche: Start by identifying niche markets that align with your interests and expertise. Think about communities or groups that have specific printing needs. For example, local sports teams, hobby clubs, or small businesses often require custom apparel or promotional items. By focusing on these niches, you can tailor your services to meet their unique demands.

Offer Personalized Solutions: Customers in niche markets appreciate personalized solutions. With DTF printing, you can offer custom designs that reflect the identity and values of these groups. Whether it’s a unique logo, a special event design, or a limited edition print, your ability to provide personalized products sets you apart from competitors.

Leverage Small Batch Production: One of the strengths of DTF printing is its ability to handle small batch production efficiently. This means you can take on small custom jobs without worrying about high setup costs or excessive inventory. You can produce exactly what your customers need, when they need it, ensuring satisfaction and repeat business.

Build Strong Relationships: Building strong relationships with your niche market customers is key to long-term success. Engage with them regularly, understand their evolving needs, and offer solutions that exceed their expectations. Happy customers are more likely to recommend your services to others, helping you grow your business through word-of-mouth.

Stay Flexible and Adaptable: Niche markets can change quickly, so staying flexible and adaptable is crucial. Keep an eye on trends and be ready to adjust your offerings as needed. This agility allows you to stay relevant and continue meeting the needs of your niche customers.

By focusing on niche markets and small custom jobs, you can carve out a profitable space in the printing industry. DTF printing equips you with the tools to deliver high-quality, personalized products that resonate with your customers. Embrace this opportunity and watch your business thrive.

Case Studies of Successful DTF Implementation

Exploring real-world examples can provide valuable insights into how DTF printing can transform small printing shops. Let’s dive into some success stories and lessons learned from industry leaders.

Small Shop Success Stories

Bright Threads Printing: This small shop in Austin, Texas, embraced DTF technology to expand its product offerings. Initially focused on screen printing, they faced challenges with high setup costs and limited fabric options. By switching to DTF, they could print on a variety of materials, including cotton and polyester. This flexibility allowed them to cater to niche markets, such as custom sportswear and eco-friendly tote bags. The owner, Sarah, noted that DTF’s low minimum order quantities enabled her to take on smaller, custom jobs without the financial strain of traditional methods.

Urban Ink Designs: Located in Portland, Oregon, Urban Ink Designs found success by integrating DTF printing into their operations. They specialized in personalized apparel for local events and small businesses. The DTF process allowed them to produce vibrant, durable prints quickly, meeting tight deadlines with ease. The shop’s owner, Mike, highlighted the cost-effectiveness of DTF, which reduced production costs by 30% compared to their previous methods. This efficiency boosted their profit margins and attracted more clients seeking high-quality custom prints.

EcoPrint Studio: This environmentally-conscious shop in San Francisco leveraged DTF’s eco-friendly options to appeal to green-minded customers. By choosing DTF powders with minimal environmental impact, they positioned themselves as leaders in sustainable printing. The ability to offer eco-friendly products without compromising on quality helped them build a loyal customer base. Their success story underscores the importance of aligning business practices with customer values.

Lessons Learned from Industry Leaders

Adaptability is Key: Industry leaders emphasize the importance of staying adaptable. DTF technology allows you to quickly respond to market trends and customer demands. By keeping an eye on emerging styles and preferences, you can use DTF to create products that resonate with your audience.

Invest in Quality Equipment: Successful businesses understand the value of investing in reliable DTF equipment. While initial costs might seem high, quality machines reduce maintenance issues and ensure consistent print quality. This investment pays off in the long run with satisfied customers and repeat business.

Focus on Training: Proper training is crucial for maximizing the benefits of DTF printing. Ensure your team understands the process and can troubleshoot common issues. Continuous learning keeps your staff updated with the latest techniques, enhancing productivity and print quality.

Embrace Customization: DTF’s ability to handle small batch production efficiently opens doors to customization. Offering personalized solutions sets you apart from competitors and attracts customers willing to pay a premium for unique products.

By learning from these success stories and industry insights, you can harness the full potential of DTF printing. Whether you’re a small shop looking to expand or an established business seeking innovation, DTF offers the tools to thrive in a competitive market.

DTF powder benefits are a game-changer for small printing shops. You gain efficiency and versatility, allowing you to produce high-quality prints on demand. This technology saves time and offers better quality compared to traditional methods like screen printing. The market for DTF has expanded rapidly, with major brands embracing its unique advantages. By integrating DTF into your operations, you future-proof your business, streamline production processes, and tap into the growing demand for custom apparel decoration. Embrace DTF to stay ahead in the competitive printing industry.

FAQ

What is DTF powder, and why is it important?

DTF powder acts as an adhesive in the DTF printing process. It helps the ink bond to the fabric, ensuring vibrant and durable prints. You sprinkle it over the printed design on a DTF film before curing. This step is crucial for achieving high-quality results. Without DTF powder, the ink wouldn’t adhere properly, leading to poor print quality.

How does DTF printing differ from traditional methods like screen printing?

DTF printing offers a more streamlined process compared to traditional methods. You don’t need separate screens for each color, which saves time and reduces labor costs. DTF allows you to handle low-volume orders efficiently, making it perfect for custom prints and niche markets. Screen printing, on the other hand, requires significant manual labor and long setup times.

Can I use DTF printing for small custom jobs?

Absolutely! DTF printing excels in handling small custom jobs. You can produce high-quality prints without worrying about high setup costs or excessive inventory. This flexibility allows you to cater to niche markets and offer personalized solutions that set you apart from competitors.

What types of fabrics can I use with DTF printing?

DTF printing works well on a variety of fabrics, including cotton and polyester. This versatility means you can cater to different customer needs without compatibility issues. Whether you’re printing on t-shirts, hoodies, or tote bags, DTF has got you covered.

How can I ensure consistent quality with DTF transfers?

To achieve consistent quality, focus on understanding the DTF process thoroughly. Optimal heat press settings play a vital role in ensuring vibrant and durable prints. Regularly maintain your equipment and train your staff to handle the machines efficiently. This approach ensures every print meets high standards.

What are some common challenges with DTF printing, and how can I overcome them?

Common challenges include managing initial costs, ensuring consistent quality, and avoiding clogging issues. You can manage costs by investing in reliable equipment and choosing the right DTF powder for your fabric type. Regular maintenance and proper training help ensure quality and prevent clogs.

Is DTF printing environmentally friendly?

DTF printing can be environmentally friendly, depending on the materials used. Consider using eco-friendly DTF powders and films to minimize environmental impact. Proper ventilation and protective gear also help ensure a safe and responsible printing process.

How can I market my DTF printing services effectively?

Focus on niche markets and tailor your marketing efforts to specific audiences. Offer exclusive, one-off designs that appeal to niche audiences. Smart advertising and business planning are key to building a successful and profitable DTF printing business.

What equipment do I need for DTF printing?

You’ll need a compatible printer, a reliable heat press, a powder applicator, and high-quality DTF film. Investing in quality equipment ensures efficient and high-quality DTF printing. This investment pays off with satisfied customers and increased profits.

How can DTF printing help future-proof my business?

DTF printing allows you to adapt to market trends, expand your service offerings, and tap into the booming print-on-demand services. By embracing DTF, you gain flexibility, quality, and profitability, allowing you to thrive in a dynamic market.