Can a normal printer really replace a DTF powder printer? You might wonder about this, especially if you’re looking to save on costs or simplify your printing setup. While normal printers serve many purposes, they often fall short in areas like print quality and durability when compared to DTF powder printers. DTF printers offer significant savings, allowing you to cut up to 50% on white ink costs alone. This makes them more economical in the long run. So, before making a decision, consider factors like cost, practicality, and the specific needs of your projects.

Key Takeaways

DTF powder printers can save you up to 50% on white ink costs, making them more economical for textile printing in the long run.

Normal printers, while versatile for documents and photos, lack the specialized inks and durability needed for high-quality textile prints.

DTF printing offers vibrant colors and excellent durability, making it ideal for custom apparel that withstands multiple washes.

Investing in a DTF printer may have a higher upfront cost, but it pays off through efficiency and lower long-term ink expenses.

Modifying a normal printer for DTF tasks can lead to compatibility issues and potential damage, making it a risky choice.

Understanding the specific needs of your projects is crucial when deciding between a normal printer and a DTF powder printer.

Understanding Normal Printers

When you think about printers, Normal Printers often come to mind first. These are the everyday machines you see in homes and offices. They handle a variety of tasks, from printing documents to producing vibrant photos. But how do they stack up against specialized printers like DTF powder printers? Let’s dive into the types and uses of normal printers to find out.

Types of Normal Printers

Normal printers come in several types, each with its own strengths:

Inkjet Printers: These are the most common. They range from small, budget-friendly models to high-end professional machines. Inkjet printers excel at printing photos and small-volume documents. They use liquid ink sprayed onto paper, which makes them great for detailed images.

Laser Printers: Known for speed and efficiency, laser printers use toner instead of ink. They are ideal for high-volume text documents. While they don’t match inkjets in photo quality, they shine in producing crisp text quickly.

All-in-One Printers: These versatile machines combine printing, scanning, copying, and sometimes faxing. They are perfect for home offices where space and functionality are key.

Common Uses and Limitations

Normal printers serve many purposes, but they have their limits:

Common Uses:

Printing documents for school or work.

Producing high-quality photos at home.

Creating flyers or brochures for small businesses.

Limitations:

Print Quality: While inkjets offer good photo quality, they can’t match the durability and vibrancy of DTF prints.

Ink Compatibility: Normal printers can’t handle the specialized inks needed for DTF printing. This limits their ability to print on textiles or other materials that require white ink.

Durability: Prints from normal printers may fade or wear over time, especially when exposed to sunlight or moisture.

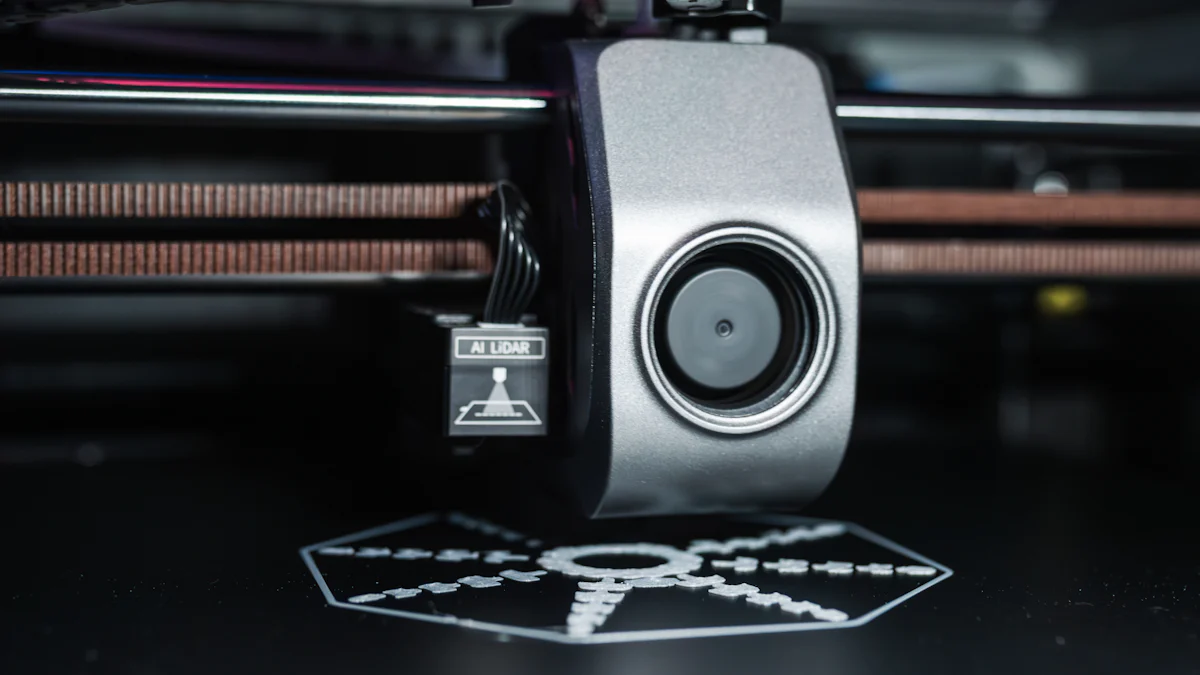

What is a DTF Powder Printer?

You might have heard about DTF Printing and wondered what makes it so special. Well, it’s a game-changer in the world of textile printing. Unlike traditional methods, DTF printing involves transferring designs onto a special film, which you then press onto fabric using heat. This technique offers vibrant colors, intricate details, and excellent durability. It’s no wonder many people prefer it for custom apparel and textile applications.

How DTF Printing Works

So, how does this magical process work? It starts with printing your design onto a special film using a DTF printer. This film acts as a carrier for the ink. Once printed, you apply a layer of adhesive powder to the wet ink on the film. This powder ensures that the design sticks to the fabric during the heat transfer process. After applying the powder, you cure the film to dry the ink and powder. Finally, you use a heat press to transfer the design from the film to the fabric. The result? A vibrant, durable print that can withstand washing and wear.

Advantages of DTF Printing

DTF printing comes with a host of benefits that make it stand out:

Versatility: You can print on a wide range of fabrics, from cotton to polyester and even blends. This flexibility means you can create custom designs on almost any garment.

Color Accuracy: DTF printing offers improved color accuracy compared to traditional screen printing. Your designs will pop with vivid colors and sharp details.

Durability: The prints are long-lasting and can endure multiple washes without fading or cracking. This durability makes DTF an excellent choice for clothing items like t-shirts and hoodies.

Efficiency: The process is faster and more streamlined than other methods. You can produce high-quality prints quickly, which is perfect for businesses looking to meet tight deadlines.

While DTF printing requires specialized equipment and supplies, its advantages often outweigh the initial investment. If you’re considering diving into the world of textile printing, DTF might just be the method you need. For more information on DTF powder and related products, check out DTF Powder China.

Key Differences Between Normal Printers and DTF Powder Printers

When you’re deciding between a normal printer and a DTF powder printer, understanding their differences is crucial. Each type of printer has its own strengths and weaknesses, which can significantly impact your printing projects.

Ink Types and Compatibility

Normal printers, like inkjet and laser models, use standard inks or toners designed for paper. These inks work well for everyday tasks but fall short when it comes to textile printing. DTF powder printers, on the other hand, use specialized textile inks. These inks are formulated to adhere to fabrics, providing vibrant colors and long-lasting prints. If you try using a normal printer for DTF tasks, you’ll face compatibility issues. The inks won’t bond properly with the film or fabric, leading to poor-quality prints.

Print Quality and Durability

Print quality and durability are where DTF powder printers truly shine. Normal printers can produce decent quality on paper, but they struggle with textiles. The prints from a normal printer may fade or wash out over time. In contrast, DTF powder printers deliver exceptional quality and durability. The prints remain vibrant and intact even after multiple washes. This makes them ideal for custom apparel and other textile applications.

“Printer A provides great quality and durability but is pricier than B and C. Printer B prints well and is moderately durable, but more cost-effective than A. Printer C has average print quality and low durability, and it’s the most affordable one.”

This comparison highlights how DTF printers, like Printer A, offer superior quality and durability, albeit at a higher cost. However, the investment often pays off in the long run due to the longevity of the prints.

Application Processes

The application process for each printer type also differs significantly. Normal printers are straightforward. You load the paper, hit print, and you’re done. DTF powder printers require a more involved process. You print the design onto a special film, apply adhesive powder, cure it, and then transfer it to the fabric using a heat press. While this process might seem complex, it ensures that the design adheres well to the fabric, resulting in a high-quality finish.

If you’re considering diving into textile printing, understanding these differences is key. For more information on DTF powder and related products, visit DTF Powder China.

Can a Normal Printer Be Modified for DTF Printing?

You might wonder if you can modify a normal printer to handle DTF printing. The idea sounds appealing, especially if you’re looking to save money. However, this process involves several steps and considerations.

Potential Modifications Needed

To transform a normal printer into a DTF printer, you need to make specific modifications. First, you must replace the standard ink cartridges with DTF-compatible inks. These inks are specially formulated to adhere to textiles, unlike regular printer inks. Next, you need to adjust the printer’s settings to accommodate the thicker DTF film. This adjustment ensures that the printer can handle the film without jamming or damaging it. Additionally, you might need to install a special RIP (Raster Image Processor) software. This software helps manage color profiles and print settings, ensuring high-quality results.

Challenges and Risks

Modifying a normal printer for DTF printing comes with its own set of challenges and risks. One major challenge is the potential for printer damage. Normal printers aren’t designed for DTF tasks, so forcing them to handle these tasks can lead to mechanical issues. You also risk voiding any warranty on your printer by making these modifications. Another concern is the environmental impact. DTF printing can generate waste and consume resources, which might not align with your sustainability goals.

“One of the drawbacks of DTF printing is its potential environmental impact, due to waste generation and resource consumption.”

This quote highlights the importance of considering environmental factors when deciding whether to modify your printer.

If you’re interested in exploring DTF printing further, consider visiting DTF Powder China for more information on DTF powder and related products. This resource can provide valuable insights and help you make an informed decision.

Pros and Cons of Using a Normal Printer for DTF Tasks

When considering whether to use a normal printer for DTF tasks, weighing the pros and cons is essential. This decision can impact your printing quality, efficiency, and overall costs.

Cost Considerations

Using a normal printer might seem like a cost-effective choice initially. You already have the equipment, so why not use it for DTF tasks? However, the reality is more complex. While you save on the initial purchase of a DTF printer, you may face higher costs in the long run. Normal printers require modifications to handle DTF printing, which can be costly and time-consuming. Additionally, the specialized inks needed for DTF printing are not compatible with standard printers, leading to potential waste and inefficiency.

On the other hand, investing in a DTF printer involves a higher upfront cost. Yet, this investment pays off over time. DTF printers are designed for efficiency and durability, saving you money on ink and maintenance. They also offer the versatility to print on various media, making them a cost-effective tool for many businesses.

Practicality and Efficiency

Normal printers are practical for everyday tasks like document printing. However, when it comes to DTF tasks, they fall short. The process of modifying a normal printer for DTF printing is complex and may not yield the desired results. You might encounter issues like poor print quality or frequent jams, which can disrupt your workflow.

In contrast, DTF printers are built for efficiency. They streamline the printing process, allowing you to produce high-quality prints quickly. This efficiency is crucial for businesses that need to meet tight deadlines or handle large orders. With a DTF printer, you can focus on creating vibrant, durable prints without worrying about technical hiccups.

Quality and Longevity of Prints

The quality and longevity of your prints are vital factors to consider. Normal printers can produce decent prints on paper, but they struggle with textiles. The prints may fade or wash out over time, especially if exposed to sunlight or moisture. This lack of durability can be a significant drawback if you’re printing custom apparel or other textile products.

DTF printers, however, excel in print quality and longevity. They use specialized inks that adhere well to fabrics, resulting in vibrant colors and sharp details. These prints can withstand multiple washes without fading or cracking, making them ideal for clothing items like t-shirts and hoodies. If quality and durability are your priorities, a DTF printer is the better choice.

For more information on DTF powder and related products, visit DTF Powder China. This resource can provide valuable insights into the benefits of using a dedicated DTF printer.

Real-World Applications and User Experiences

Case Studies

When you explore the world of DTF printing, real-world applications can offer valuable insights. Let’s dive into some case studies that highlight how different users have successfully integrated DTF printing into their workflows.

Small Business Success: A local t-shirt printing business decided to switch from traditional screen printing to DTF printing. They found that using a DTF printer allowed them to produce more vibrant and durable designs. This switch not only improved their product quality but also reduced production time. The business owner noted that the initial investment in a DTF printer paid off quickly due to increased customer satisfaction and repeat orders.

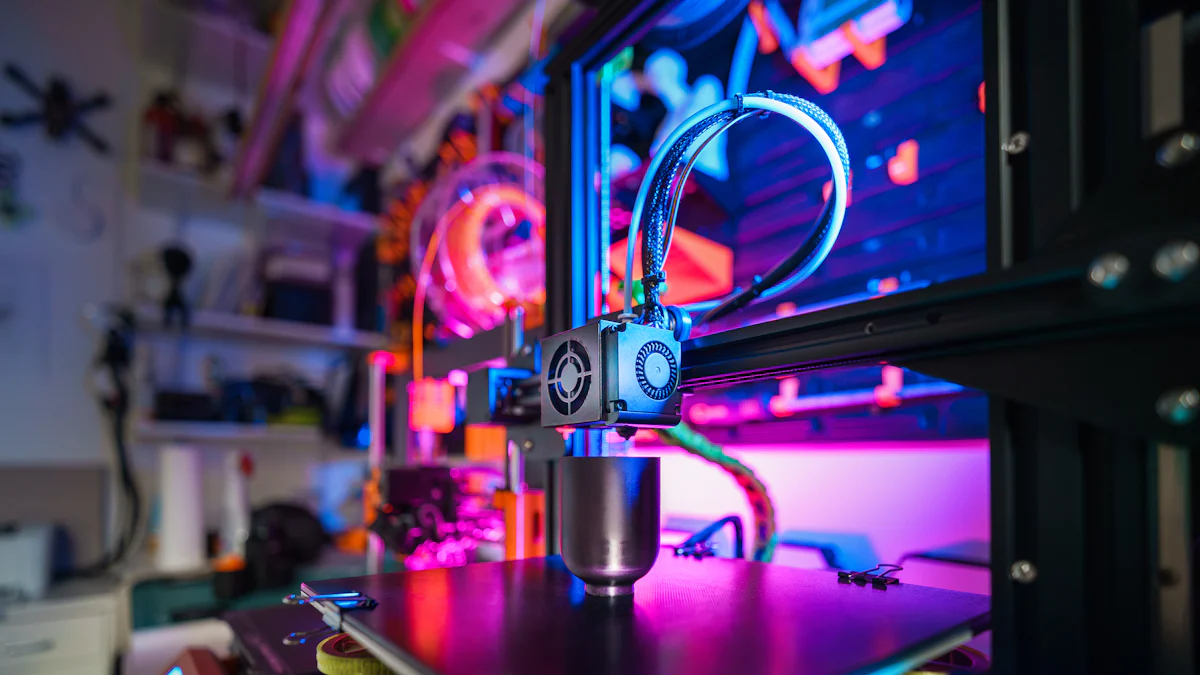

Artisan Apparel: An independent designer used an adapted inkjet printer for DTF printing. By converting a standard inkjet printer with six ink tanks, they managed to create intricate designs on various fabrics. This approach allowed them to offer custom apparel at a competitive price. The designer appreciated the flexibility of using a converted printer, although they acknowledged the slower speed compared to dedicated DTF machines like the Epson L1800.

Educational Institutions: A university art department incorporated DTF printing into their curriculum. Students used DTF printers to experiment with textile designs, gaining hands-on experience with modern printing techniques. The department found that DTF printing provided a cost-effective way to teach students about color accuracy and fabric compatibility.

These case studies demonstrate the versatility and effectiveness of DTF printing across different sectors. Whether you’re a small business owner, an independent designer, or an educator, DTF printing can offer unique advantages tailored to your needs.

User Testimonials

Hearing from those who have firsthand experience with DTF printing can provide you with practical insights. Here are some testimonials from users who have embraced this technology:

“Switching to DTF printing transformed my business. The colors are more vibrant, and the prints last longer. My customers love the quality!” – Sarah, Small Business Owner

“I was skeptical about converting my inkjet printer for DTF tasks, but it was worth it. The process was straightforward, and the results exceeded my expectations.” – Mike, Independent Designer

“Our students love working with DTF printers. It gives them a chance to explore their creativity and learn about modern printing methods.” – Dr. Emily, University Professor

These testimonials highlight the positive impact DTF printing can have on various projects. If you’re considering making the switch, these real-world experiences might just inspire you to take the plunge.

For more information on DTF powder and related products, visit DTF Powder China. This resource can help you explore the possibilities of DTF printing and find the right solutions for your needs.

Making an Informed Decision

Choosing between a normal printer and a DTF powder printer can feel overwhelming. You want to make the right choice for your needs, so let’s break it down into manageable parts.

Factors to Consider

When deciding on a printer for DTF tasks, several factors come into play:

Quality: You want prints that look great and last long. DTF printers excel in this area, offering vibrant colors and durability. Normal printers might not meet these standards, especially for textiles.

Durability: Consider how well the prints will hold up over time. DTF prints are known for their resilience, even after multiple washes. This durability is crucial if you’re printing on clothing or other fabric items.

Cost: Initial costs can be deceiving. While a normal printer might seem cheaper upfront, the long-term expenses of modifications and specialized inks can add up. DTF printers, though pricier initially, often save money in the long run due to their efficiency and lower ink costs.

Configuration and Components: Understanding the setup of a DTF printer is vital. Some printers might not be worth the investment despite being from big brands. Others, with high performance but lesser-known names, could be hidden gems. Knowing what each printer offers helps you avoid costly mistakes.

In wrapping up, it’s clear that a normal printer can’t fully replace a DTF powder printer. While normal printers handle everyday tasks well, they lack the specialized capabilities needed for high-quality textile printing. DTF printers excel in producing vibrant, durable prints, making them ideal for custom apparel. If you’re considering DTF transfers, prioritize factors like resolution capabilities and printer compatibility. Investing in a dedicated DTF printer ensures you meet your specific needs effectively. For more insights on DTF powder and related products, visit DTF Powder China.

FAQ

What are some common mistakes encountered in DTF printing?

DTF printing, like any other printing technique, has its own set of challenges. One common mistake is not properly curing the ink, which can lead to prints that fade or peel. Another issue is using incorrect temperature settings during the heat transfer process, resulting in poor adhesion. To avoid these pitfalls, always follow the manufacturer’s guidelines and conduct test prints to ensure high-quality results.

How does DTF printing work?

DTF printing involves printing your design onto a special film, applying adhesive powder, and then transferring it onto fabric using a heat press. This method allows for vibrant colors and durable prints. It’s widely used for custom apparel and offers flexibility in printing on various fabrics. For more detailed steps, you can explore resources like DTF Powder.

Can I use a normal printer for DTF tasks?

While you might consider using a normal printer for DTF tasks, it’s not recommended without modifications. Normal printers lack the capability to handle specialized DTF inks and films. Attempting to use them without proper adjustments can lead to poor print quality and potential damage to the printer.

What are the main categories of DTF printers?

DTF printers come in various types to suit different needs and budgets. Some are designed for small-scale operations, while others cater to mass production. Understanding the different categories helps you choose the right printer for your specific requirements. Consider factors like print speed, resolution, and compatibility with different fabrics when making your decision.

Are there myths about DTF printing?

Yes, several myths surround DTF printing. One common misconception is that it’s too expensive for small businesses. However, the initial investment often pays off due to the efficiency and durability of the prints. Another myth is that DTF printing is only suitable for large-scale operations, but many small businesses successfully use it for custom apparel.

What are some frequently asked questions about DTF printing?

Here are some FAQs we often receive about DTF printing:

How long do DTF prints last?

Can I print on dark fabrics?

What maintenance does a DTF printer require?

These questions highlight the versatility and practicality of DTF printing for various applications.

Where can I find a DTF Printer Comparison?

You can find comprehensive comparisons of DTF printers online, which detail their features, pros, and cons. These comparisons help you make an informed choice by highlighting differences in print quality, speed, and cost. Look for reviews and user testimonials to gain insights into real-world performance.

What are some myths and facts about DTF printing?

This blog aims to bust common myths and provide facts about DTF printing. For instance, while some believe DTF printing is complex, it actually offers a straightforward process once you understand the basics. The facts will help you decide if DTF printing suits your needs.

How can I ensure high-quality DTF prints?

To achieve high-quality DTF prints, focus on using the right materials and settings. Ensure your printer is properly calibrated, and use high-quality films and powders. Regular maintenance of your printer also plays a crucial role in maintaining print quality. Always conduct test prints to fine-tune your process.

For more information on DTF powder and related products, visit DTF Powder. This resource can guide you in exploring the possibilities of DTF printing and finding the right solutions for your needs.