Achieving flawless DTF curing results is essential for ensuring high-quality and durable prints. Proper curing involves setting the right temperature and time, which directly impacts the adhesion of the ink and powder to the fabric. Larger prints or those with heavy ink layers may require adjustments in curing parameters to achieve optimal results. By mastering these techniques, you can enhance the longevity and vibrancy of your DTF prints, making them stand out in terms of quality and durability.

Key Takeaways

Use the right equipment and maintain a temperature range of 320-350°F for 30-60 seconds to ensure proper curing of DTF prints.

Monitor the curing process closely to identify any issues early, adjusting temperature and time settings as necessary for optimal results.

Conduct visual inspections and adhesion tests to identify uncured areas, ensuring the quality and durability of your prints.

If necessary, perform a second cure to solidify the bond between ink and fabric, especially for larger designs or thicker ink layers.

Adjust pressure settings based on the fabric type, typically between 60-80 PSI, to enhance adhesion without damaging the material.

Implement quality control checks and standardize procedures when scaling up for mass production to maintain consistent results.

Continuously learn and adapt your techniques in DTF printing to stay ahead in the field and improve print quality.

Achieving Flawless DTF Curing

Key Techniques for Effective Curing

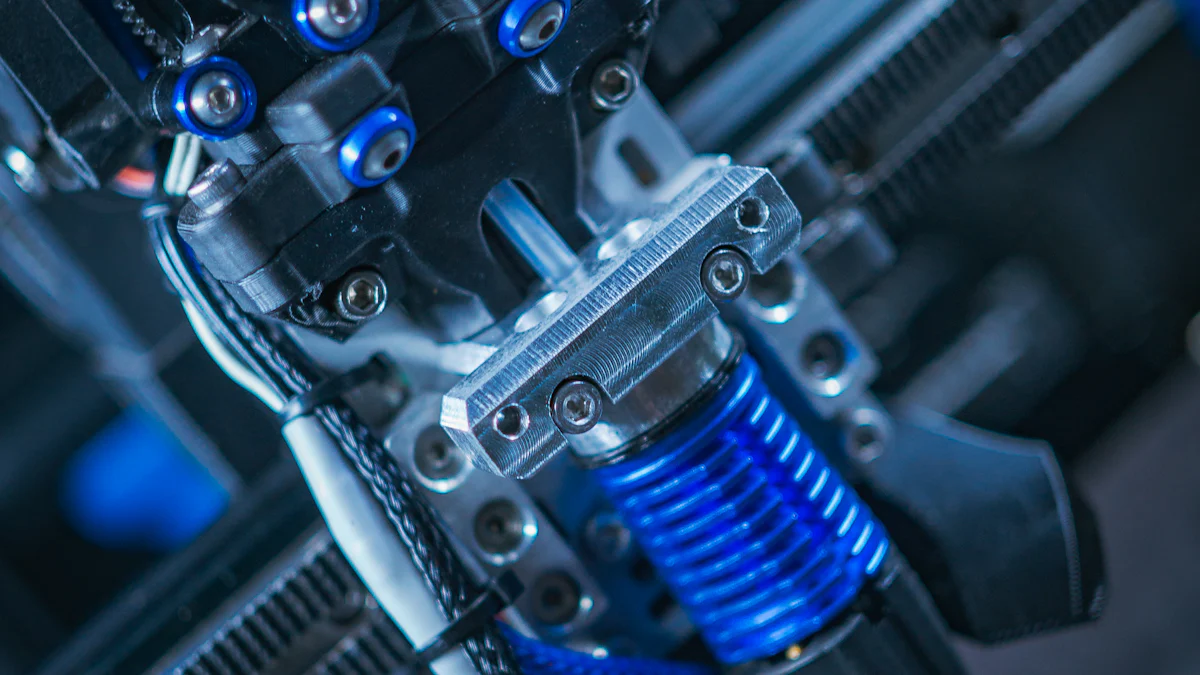

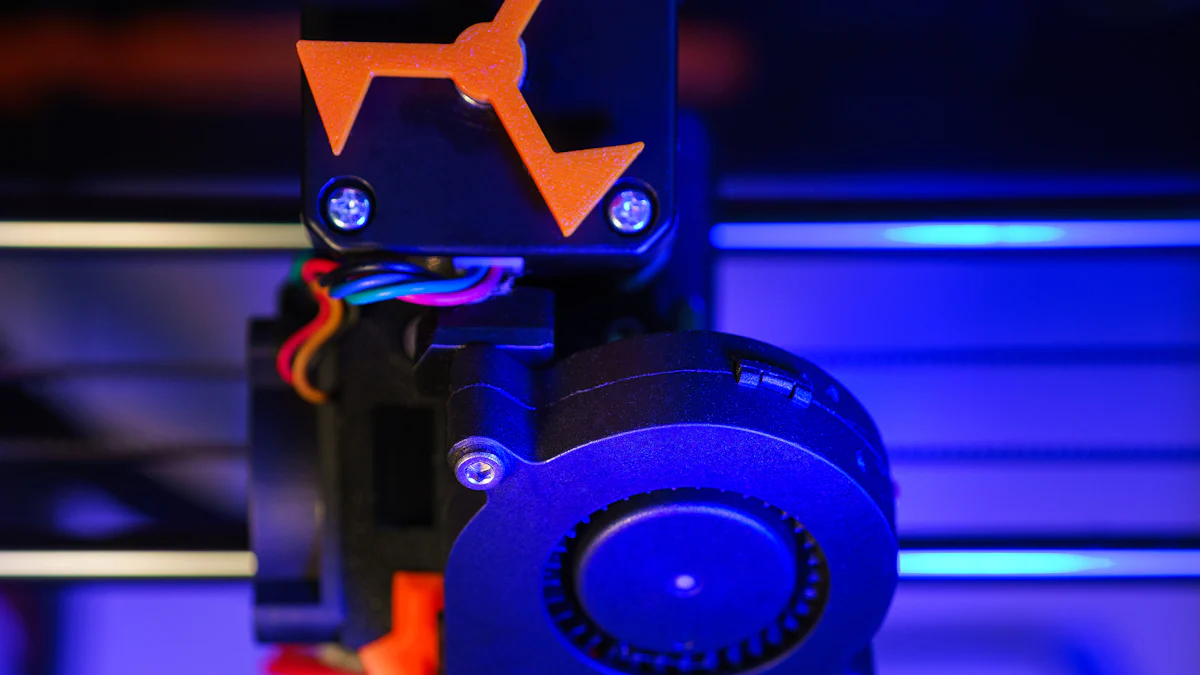

To achieve flawless DTF curing, you must focus on several key techniques. First, ensure that you use the right equipment. DTF Curing Equipment is essential for heating the DTF powder and ink to the correct temperature. This process bonds them effectively, resulting in a shiny, textured finish. You should aim for a temperature range of 320-350°F and a curing time of 30-60 seconds. This range helps ensure that your prints look good and last long.

Next, monitor the curing process closely. Keep an eye on the drying process to prevent any mishaps. If you notice any issues, such as incomplete curing, verify the initial curing temperature and duration. Adjust these settings as needed to correct any problems. Experimenting with different ink volumes can also help you achieve the best results.

Importance of Temperature and Time Settings

Temperature and time settings play a crucial role in DTF curing. Setting the right temperature ensures that the adhesive powder and ink adhere properly to the fabric. If the temperature is too low, the print may not cure correctly, leading to poor adhesion and durability. On the other hand, if the temperature is too high, it can cause over-curing, which affects the print’s appearance and texture.

Time settings are equally important. Curing for too short a time may result in incomplete bonding, while too long can lead to over-curing. You should aim for a balance that allows the print to cure thoroughly without compromising its quality. Regularly check your equipment’s settings and make adjustments based on the specific requirements of each print job.

By mastering these techniques and paying close attention to temperature and time settings, you can achieve flawless DTF curing results. This will enhance the longevity and vibrancy of your prints, ensuring they stand out in terms of quality and durability.

Identifying Uncured Areas

Identifying uncured areas in your DTF prints is crucial for ensuring the quality and durability of your final product. Uncured sections can lead to poor adhesion, affecting the print’s longevity. You can use several methods to detect these problematic areas effectively.

Visual Inspection Techniques

Visual inspection is one of the simplest yet most effective ways to identify uncured areas. Start by examining the print under good lighting conditions. Look for signs of stickiness, dullness, or flaking on the surface. These are indicators that the curing process might not have been completed successfully. The cured adhesive powder should appear clear and fully integrated with the underlying ink. If you notice any unmelted powder spots, it suggests inadequate curing. This can compromise the print’s durability.

To enhance your inspection, consider using a heat gun. Gently apply heat to suspect areas and observe any changes. Properly cured sections will not alter significantly, while uncured areas may show signs of melting or further blending. This technique helps confirm whether the curing process was thorough.

Testing for Adhesion

Testing for adhesion provides another layer of assurance that your DTF curing process was successful. Conduct a touch test by gently running your fingers over the print. A smooth surface without any sticky or powdery residue indicates proper curing. If you feel any roughness or detect unmelted powder, it signifies incomplete curing.

For a more thorough assessment, you can perform a peel test. Carefully attempt to lift a small section of the print. If it peels away easily, the curing process needs adjustment. Properly cured prints should resist peeling, demonstrating strong adhesion to the fabric.

By employing these visual and tactile techniques, you can effectively identify uncured areas in your DTF prints. This ensures that your prints maintain their quality and durability, providing you with flawless results.

Preparing for a Second Cure

In some cases, a second curing process becomes necessary to ensure the durability and quality of your DTF prints. This additional step can help solidify the bond between the ink and fabric, providing a more robust finish. Understanding when and how to perform a second cure can significantly enhance the final product.

When is a Second Cure Necessary?

You might wonder when a second cure is required. Typically, a second curing process is essential when the initial cure does not achieve the desired adhesion or durability. This can happen if the print involves larger designs or thicker ink layers. These factors may prevent the ink and adhesive powder from bonding effectively during the first cure.

A second cure also becomes crucial if you notice any uncured areas after the initial process. By applying a second round of heat, you can ensure that all sections of the print receive adequate curing. This step helps maintain the integrity of the print, preventing peeling or fading over time.

Steps for Effective Second Curing

To perform a second cure effectively, follow these steps:

Assess the Print: Begin by inspecting the print for any uncured areas. Look for signs of stickiness or dullness, which indicate incomplete curing.

Set the Temperature and Time: Use the same temperature and time settings as the initial cure. Consistency in these parameters helps prevent damage and ensures a durable finish. Typically, a temperature range of 320-350°F for 30-60 seconds works well.

Apply Heat Evenly: Ensure that the heat is distributed evenly across the entire print. This uniform application helps achieve a consistent cure, enhancing the print’s overall quality.

Monitor the Process: Keep a close eye on the curing process. Watch for any changes in the print’s appearance, ensuring that the second cure addresses any previous issues.

By following these steps, you can effectively perform a second cure, ensuring that your DTF prints achieve optimal bonding and durability. This additional process can make a significant difference in the longevity and appearance of your prints.

Setting the Correct Temperature and Pressure

Achieving flawless DTF curing results requires setting the correct temperature and pressure. These factors play a crucial role in ensuring that your prints adhere properly to the fabric and maintain their quality over time.

Recommended Temperature Ranges

For optimal DTF curing, you should aim for a temperature range between 320°F and 350°F. This range ensures that the adhesive powder and ink bond effectively with the fabric. Using a timer is essential to maintain consistency. Most DTF powders require curing for 30 to 60 seconds within this temperature range. This duration allows the powder to melt and integrate seamlessly with the ink, resulting in a durable and vibrant print.

Adjusting Pressure for Different Materials

Pressure settings are equally important in the DTF curing process. Different materials may require adjustments to the pressure applied during curing. For most fabrics, a pressure setting of 60 to 80 PSI works well. This range provides enough force to ensure proper adhesion without damaging the fabric. However, you should always consider the specific characteristics of the material you are working with. Thicker fabrics might need slightly higher pressure, while delicate materials may require a gentler touch.

By carefully setting the temperature and pressure, you can enhance the quality and durability of your DTF prints. These adjustments ensure that your prints not only look great but also stand the test of time.

Troubleshooting Common Issues

In the world of DTF curing, you might encounter some common issues that can affect the quality and durability of your prints. Understanding how to troubleshoot these problems is essential for achieving flawless results.

Addressing Incomplete Curing

Incomplete curing can lead to prints that lack adhesion and durability. You need to address this issue promptly to ensure your prints maintain their quality. Here are some steps to help you tackle incomplete curing:

Check Temperature and Time Settings: Ensure that your curing equipment is set to the recommended temperature range of 320°F to 350°F. Verify that the curing time is between 30 to 60 seconds. These settings are crucial for proper bonding of the adhesive powder and ink to the fabric.

Inspect Equipment: Regularly inspect your curing equipment for any malfunctions. A faulty heat press or conveyor dryer can lead to uneven heat distribution, resulting in incomplete curing. Make sure all components are functioning correctly.

Monitor the Process: Keep a close eye on the curing process. If you notice any signs of stickiness or dullness on the print surface, it indicates incomplete curing. Adjust the temperature or time settings as needed to achieve optimal results.

Experiment with Ink Volumes: Sometimes, adjusting the volume of ink used in the print can help achieve better curing results. Test different ink volumes to find the right balance for your specific design.

By following these steps, you can effectively address incomplete curing and ensure your DTF prints are of high quality and durability.

Dealing with Over-Curing

Over-curing can also pose challenges in DTF printing. It can lead to prints that appear brittle or have a compromised texture. Here’s how you can deal with over-curing:

Reduce Temperature and Time: If you suspect over-curing, try reducing the temperature or curing time slightly. This adjustment can prevent the adhesive powder and ink from becoming too rigid or brittle.

Use a Heat Gun for Spot Curing: For areas that appear over-cured, consider using a heat gun to gently reheat and soften the print. This technique can help restore flexibility and improve the overall appearance.

Test Different Curing Methods: Explore alternative curing methods, such as using a heat press or oven, to see if they yield better results. Different methods may offer more control over the curing process, allowing you to avoid over-curing.

Follow Manufacturer Guidelines: Always adhere to the manufacturer’s guidelines for curing DTF prints. These guidelines provide valuable insights into the optimal settings for your specific materials and equipment.

By implementing these strategies, you can effectively manage over-curing and maintain the quality and longevity of your DTF prints.

DTF Curing in Mass Production

Scaling up the DTF curing process for mass production requires careful planning and the right equipment. When you transition from small-scale operations to larger batches, you must consider several factors to maintain efficiency and quality.

Scaling Up the Curing Process

In mass production, you need to choose equipment that can handle larger volumes without compromising on quality. Conveyor dryers and curing ovens are ideal for large-scale operations. These machines provide consistent heat distribution, ensuring each print receives the same level of curing. Unlike small-scale setups that might use heat presses, conveyor dryers allow for continuous processing, which is crucial when dealing with high volumes.

To scale up effectively, you should:

Invest in High-Capacity Equipment: Conveyor dryers and curing ovens are designed for mass production. They offer uniform heat application, which is essential for consistent results across large batches.

Optimize Workflow: Arrange your workspace to facilitate a smooth flow of materials. This setup minimizes downtime and maximizes productivity.

Monitor Consistency: Regularly check the equipment settings to ensure they remain within the recommended temperature and time ranges. Consistency is key to maintaining quality.

Maintaining Quality in Large Batches

Maintaining quality in large batches can be challenging, but it’s achievable with the right strategies. You must focus on both the curing process and the materials used.

Quality Control Checks: Implement regular quality checks throughout the production process. Inspect random samples from each batch to ensure they meet your standards.

Standardize Procedures: Develop standard operating procedures for every step of the DTF curing process. This standardization helps maintain consistency and reduces the risk of errors.

Train Your Team: Ensure that your team understands the importance of each step in the curing process. Proper training helps prevent mistakes and ensures everyone follows the established procedures.

By scaling up your DTF curing process thoughtfully and maintaining rigorous quality control, you can achieve flawless results even in mass production. This approach ensures that your prints remain vibrant and durable, regardless of the batch size.

Achieving flawless DTF curing results is crucial for ensuring your prints are vibrant, durable, and long-lasting. By mastering the techniques discussed, you can significantly enhance the quality of your DTF prints. Remember to apply the tips on temperature, time, and pressure settings to improve your print quality. Continuous learning and adaptation in DTF printing will keep you ahead in this dynamic field. As you refine your skills, your prints will not only meet but exceed expectations, showcasing the true potential of DTF technology.

FAQ

What is the importance of curing in DTF printing?

Curing plays a crucial role in DTF printing. It ensures that your prints last longer, look better, and remain durable. By curing, you help the adhesive, ink, and fabric bond effectively. This bonding is essential for achieving high-quality prints. For optimal results, cure the DTF powder at temperatures between 320-350°F for 30-60 seconds.

How can you fix a DTF print that hasn’t cured properly?

If your DTF print hasn’t cured properly, you can take steps to correct it. First, check that you used the correct temperature and duration during the initial curing process. If the print appears wet or oily, it indicates inadequate curing. Ensure the print is clean and free of contaminants before attempting to re-cure it.

Is curing DTF powder necessary for achieving the best print quality and durability?

Yes, curing DTF powder is essential for achieving the best print quality and durability. Most DTF powders require curing for 30 to 60 seconds at temperatures ranging from 320 to 350 degrees Fahrenheit. Additionally, applying pressure between 60 to 80 PSI helps ensure proper adhesion and durability.

What should you do if you notice uncured areas in your DTF print?

If you spot uncured areas in your DTF print, perform a visual inspection under good lighting. Look for signs of stickiness or dullness. These indicate incomplete curing. You can also conduct a touch test to check for any roughness or unmelted powder. If necessary, apply a second cure to address these areas.

Can you use different curing methods for DTF printing?

Yes, you can explore different curing methods for DTF printing. While conveyor dryers and curing ovens are popular choices, you might also consider using a heat press or oven. Each method offers varying levels of control over the curing process. Experimenting with different techniques can help you find the best fit for your specific needs.

How do you ensure consistent results in mass production of DTF prints?

To ensure consistent results in mass production, invest in high-capacity equipment like conveyor dryers. These machines provide uniform heat distribution, crucial for large batches. Implement regular quality control checks and standardize procedures. Training your team on the importance of each step in the curing process also helps maintain consistency.

What are the common issues faced during DTF curing, and how can you troubleshoot them?

Common issues during DTF curing include incomplete curing and over-curing. To address incomplete curing, verify your temperature and time settings. Inspect your equipment for malfunctions. For over-curing, reduce the temperature or curing time slightly. Using a heat gun for spot curing can also help restore flexibility to over-cured areas.

Why is it important to set the correct temperature and pressure during DTF curing?

Setting the correct temperature and pressure is vital for ensuring your prints adhere properly to the fabric. The recommended temperature range is 320°F to 350°F, with a curing time of 30 to 60 seconds. Pressure settings between 60 to 80 PSI work well for most fabrics. These parameters help achieve durable and vibrant prints.