When it comes to choosing the best sportswear printing methods, you need to consider several key factors. The type of fabric plays a crucial role. For instance, flex printing works well on polyester and spandex, offering durability and a glossy finish. Customization has become a major trend, driving the demand for personalized sportswear. Understanding the benefits and limitations of each method helps you make informed decisions. Whether you’re looking for vibrant colors or cost-effective solutions, knowing what suits your needs ensures you get the best results for your sportswear.

Key Takeaways

Consider the fabric type when choosing a printing method; some methods work better on specific materials like polyester or cotton.

For large orders with simple designs, screen printing is cost-effective and offers vibrant, durable results.

Digital Direct to Garment (DTG) printing is ideal for intricate designs and small orders, providing high-quality, detailed prints.

Direct to Film (DTF) printing combines vivid colors and durability, making it a versatile choice for various fabrics.

Sublimation printing is perfect for creating full-color designs on synthetic fabrics, ensuring long-lasting and breathable sportswear.

Embroidery adds a professional touch and durability to sportswear, making it suitable for team uniforms and corporate apparel.

Evaluate your order size and design complexity to select the most efficient and cost-effective printing method for your needs.

Screen Printing

Screen printing stands out as one of the best sportswear printing methods, especially when you need vibrant and durable prints. This technique uses thicker inks, which result in long-lasting and brilliant colors. You can apply it to various fabrics like cotton, polyester, and blends. It’s a versatile method that has been around for ages, constantly evolving to meet modern demands.

Benefits

Cost-Effectiveness: Screen printing becomes more economical with larger orders. If you’re planning to print over 500 pieces, this method can save you money.

Durability: The thicker inks used in screen printing ensure that the designs last longer, even after multiple washes. This makes it ideal for sportswear that undergoes frequent use.

Vibrant Colors: The technique allows for bright and true-to-life colors, making your sportswear stand out. Even on dark fabrics, screen printing delivers impressive results.

Versatility: Besides fabrics, screen printing can be used on various surfaces like paper, glass, metal, and plastic. This versatility makes it a popular choice for different types of products.

Limitations

Complex Designs: Screen printing is not the best option for designs with many colors or intricate details. Fine lines and complex gradients may not translate well.

Setup Costs: For small orders, the initial setup costs can be high, making it less cost-effective for limited quantities.

Time-Consuming: Compared to methods like Direct-to-Garment (DTG) printing, screen printing can be slower, especially for detailed designs.

Ideal Use Cases

Large Bulk Orders: If you’re printing custom team shirts or any large quantity of apparel, screen printing is a great choice. It offers a balance of quality and cost-effectiveness.

Simple Designs: Designs with solid colors and bold lines work best with screen printing. It’s perfect for logos or text-based graphics.

Dark Fabrics: When you need vibrant prints on dark materials, screen printing excels. The thick inks ensure that the colors pop against the fabric.

Digital Direct to Garment (DTG)

Digital Direct to Garment (DTG) printing is a modern marvel in the world of sportswear customization. This method uses a specialized inkjet printer to apply water-based ink directly onto the fabric. You don’t need stencils or screens, which makes DTG a flexible choice for intricate designs. Let’s dive into what makes DTG one of the best sportswear printing methods available today.

Benefits

High-Fidelity Designs: DTG printing excels at producing detailed and full-color designs. You can achieve an unlimited range of colors, making it perfect for complex graphics and photographs.

Soft Feel: The prints are soft to the touch because the ink penetrates the fabric. This ensures comfort, especially important for sportswear that needs to move with you.

No Setup Costs: Unlike screen printing, DTG doesn’t require setup costs for each color. This makes it ideal for small orders or one-off designs.

Quick Turnaround: With DTG, you can print directly from a digital file. This speeds up the process, allowing for faster production times.

Limitations

Fading Concerns: DTG prints can fade over time, especially with frequent washing. Proper care is essential to maintain the print’s longevity.

Fabric Limitations: This method works best on cotton and cotton-blend garments. It may not be suitable for all types of sportswear fabrics, like polyester.

Cost for Large Orders: While great for small batches, DTG can become costly for large quantities compared to other methods like screen printing.

Ideal Use Cases

Small Orders: If you’re looking to print a limited number of items, DTG is a cost-effective choice. You avoid the high setup fees associated with other methods.

Complex Designs: For designs with intricate details or a wide range of colors, DTG shines. You can print anything from detailed logos to vibrant images.

Personalized Apparel: DTG is perfect for personalized sportswear. Whether it’s a custom jersey or a unique team shirt, you can easily create one-of-a-kind pieces.

Flex Printing

Flex printing offers a unique approach to sportswear customization. This method involves cutting designs from colored vinyl sheets and then heat-pressing them onto the fabric. It’s a popular choice for those seeking a durable and glossy finish, especially on polyester and spandex materials.

Benefits

Durability: Flex printing provides a robust finish that withstands frequent washing and wear. The vinyl material ensures that your designs remain intact over time, making it a reliable option for sportswear.

Vibrant Colors: You can achieve bright and bold colors with flex printing. The vinyl sheets come in a variety of hues, allowing you to create eye-catching designs that stand out on the field or court.

Glossy Finish: If you’re looking for a sleek and shiny appearance, flex printing delivers. The glossy finish adds a professional touch to your sportswear, enhancing its overall appeal.

Ideal for Logos: Flex printing excels at producing crisp and clear logos. The precision of the cut ensures that even small details are captured accurately, making it perfect for branding purposes.

Limitations

Limited Color Options: Flex printing restricts you to a maximum of three colors per design. This limitation can be a drawback if your design requires a broader color palette.

Design Complexity: The method is not suitable for intricate designs or gradients. Simple shapes and solid colors work best, so consider this when planning your artwork.

Longer Delivery Times: The process of cutting and applying vinyl can take longer than other methods. If you’re on a tight deadline, this might not be the most efficient choice.

Ideal Use Cases

Team Logos: Flex printing is perfect for team jerseys and uniforms. You can create bold and durable logos that withstand the rigors of sports activities.

Polyester and Spandex Fabrics: This method works exceptionally well on stretchy materials. The vinyl adheres smoothly, maintaining the fabric’s flexibility and comfort.

Small to Medium Orders: If you’re not ordering in bulk, flex printing offers a cost-effective solution. You can produce high-quality designs without the need for large quantities.

Direct to Film (DTF)

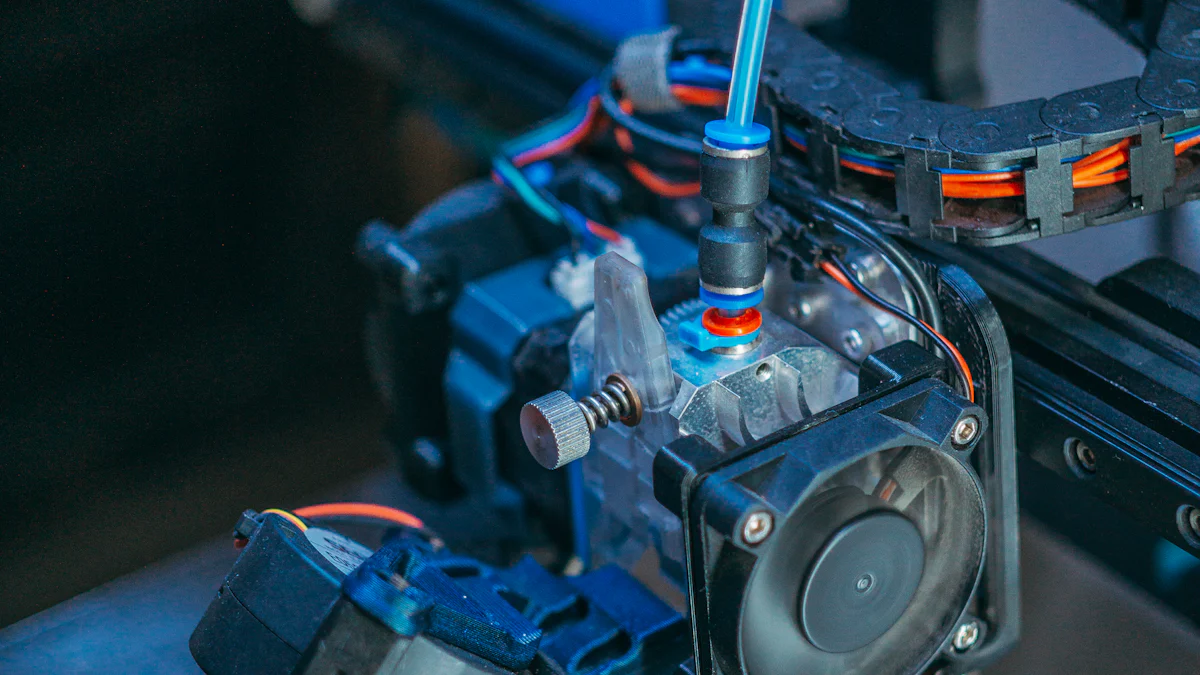

Direct to Film (DTF) printing is gaining traction as one of the best sportswear printing methods. This innovative technique involves printing designs onto a special film, which you then transfer onto the fabric using heat and pressure. DTF offers a unique blend of vivid colors and versatility, making it a popular choice for sportswear enthusiasts.

Benefits

Vivid Colors: DTF printing excels in producing vibrant and eye-catching colors. The method allows for a wide color gamut, ensuring your designs pop on any fabric. An expert in the field notes that DTF is “best for vivid colors and blended fabrics,” highlighting its ability to deliver striking visuals.

Versatility: You can use DTF on a variety of fabrics, including cotton, polyester, and blends. This flexibility makes it suitable for different types of sportswear, from jerseys to leggings.

Durability: The prints created with DTF are highly durable. They withstand frequent washing and wear, maintaining their quality over time. This durability is crucial for sportswear that sees regular use.

No Fabric Limitations: Unlike some other methods, DTF doesn’t restrict you to specific fabric types. You can achieve excellent results on both light and dark materials, expanding your design possibilities.

Limitations

Initial Setup Costs: While DTF offers many advantages, the initial setup costs can be higher compared to other methods. Investing in the right equipment and materials is essential to achieve the best results.

Learning Curve: Mastering DTF printing requires some practice. You need to understand the nuances of the process to ensure high-quality prints. However, once you get the hang of it, the results are worth the effort.

Time-Consuming for Large Orders: For bulk orders, DTF might take longer than methods like screen printing. The process involves multiple steps, which can extend production times.

Ideal Use Cases

Custom Sportswear: DTF is perfect for creating personalized sportswear. Whether you’re designing custom jerseys or unique team apparel, this method allows for intricate and colorful designs.

Blended Fabrics: If you’re working with blended fabrics, DTF shines. It provides excellent adhesion and color vibrancy, ensuring your designs look great on various material types.

Small to Medium Orders: For smaller batches, DTF offers a cost-effective solution. You can produce high-quality prints without the need for large quantities, making it ideal for limited runs or special editions.

Case Study: A local sports team recently switched to DTF printing for their custom jerseys. They found that the vibrant colors and durability of the prints significantly enhanced the team’s appearance on the field. The flexibility of DTF allowed them to experiment with different designs and fabrics, resulting in a unique and professional look.

Sublimation

Sublimation printing has become a game-changer in the world of sportswear. This method, which gained popularity in the late 20th century, allows you to create vibrant, full-color designs that cover the entire surface of a fabric. It’s particularly effective on synthetic materials like polyester, making it a favorite for sports apparel.

Benefits

Vibrant Colors: Sublimation printing excels at producing stunning, full-color designs. The colors are bright and vivid, ensuring your sportswear stands out. You can achieve intricate patterns and detailed graphics with ease.

Durability: The sublimation process embeds the ink into the fabric, resulting in long-lasting designs. Your prints won’t crack, peel, or fade, even after multiple washes. This durability is perfect for sportswear that needs to withstand rigorous use.

Breathability: Sublimation doesn’t add any extra layers to the fabric. This means your sportswear remains breathable and comfortable, crucial for athletic activities.

Seamless Designs: You can print over seams and zippers without any issues. This allows for continuous designs that look professional and polished.

Limitations

Fabric Restrictions: Sublimation works best on polyester and other synthetic fabrics. If you’re working with cotton or natural fibers, this method may not be suitable.

Initial Costs: The equipment and materials for sublimation can be expensive. However, once you have the setup, the cost per print is relatively low.

Color Limitations on Dark Fabrics: Sublimation is less effective on dark fabrics. The colors may not appear as vibrant, so it’s best used on lighter materials.

Ideal Use Cases

Custom Sportswear: Sublimation is perfect for creating personalized sports apparel. Whether you’re designing team jerseys or unique workout gear, this method allows for creativity and customization.

Promotional Items: If you’re looking to create promotional sportswear, sublimation offers a cost-effective solution. You can produce eye-catching designs that leave a lasting impression.

Polyester Fabrics: For any sportswear made from polyester, sublimation is the way to go. It ensures high-quality prints that maintain the fabric’s flexibility and comfort.

Case Study: A local gym recently adopted sublimation printing for their custom workout gear. They found that the vibrant colors and seamless designs significantly enhanced their brand image. Members loved the breathable and durable apparel, leading to increased sales and customer satisfaction.

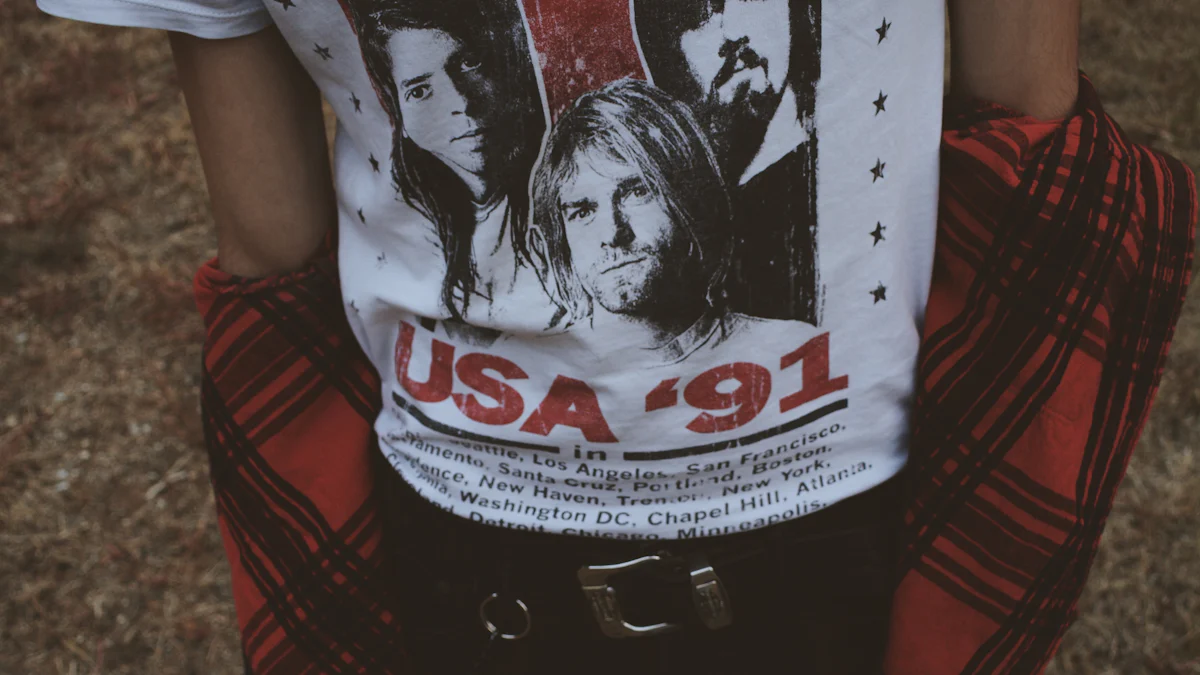

Vinyl Cutting

Vinyl cutting stands out as a fantastic method for creating durable and high-definition designs on sportswear. This technique involves cutting designs from sheets of colored vinyl and then heat-pressing them onto the fabric. It’s a popular choice for those who want crisp, clean lines and vibrant colors.

Benefits

Durability: Vinyl cutting offers exceptional durability. The vinyl material withstands frequent washing and wear, ensuring your designs remain intact over time. This makes it an excellent choice for sportswear that needs to endure rigorous use.

High-Definition Designs: You can achieve sharp and precise designs with vinyl cutting. The method allows for clean edges and vibrant colors, making your sportswear stand out. According to VS Tees, vinyl cutting is perfect for creating durable, high-definition designs on t-shirts.

Variety of Colors and Textures: Vinyl sheets come in a wide range of colors and textures, including matte, glossy, and metallic finishes. This variety allows you to create unique and eye-catching designs that suit your style.

No Setup Costs: Unlike screen printing, vinyl cutting doesn’t require setup costs for each design. This makes it ideal for small orders or one-off designs.

Limitations

Limited Design Complexity: Vinyl cutting works best for simple designs with solid colors. Intricate details or gradients may not translate well, so it’s important to keep your designs straightforward.

Time-Consuming for Large Orders: The process of cutting and applying vinyl can be time-consuming, especially for large orders. If you’re on a tight deadline, this might not be the most efficient choice.

Not Suitable for All Fabrics: Vinyl cutting works best on smooth fabrics. It may not adhere well to textured or stretchy materials, so consider the fabric type when choosing this method.

Ideal Use Cases

Team Logos and Numbers: Vinyl cutting is perfect for creating team logos and numbers on jerseys. You can achieve bold and durable designs that withstand the rigors of sports activities.

Small to Medium Orders: If you’re not ordering in bulk, vinyl cutting offers a cost-effective solution. You can produce high-quality designs without the need for large quantities.

Personalized Apparel: For personalized sportswear, vinyl cutting allows you to create unique and custom designs. Whether it’s a name, number, or logo, you can easily add personal touches to your apparel.

Case Study: A local soccer team recently switched to vinyl cutting for their custom jerseys. They found that the high-definition designs and durability of the prints significantly enhanced the team’s appearance on the field. The flexibility of vinyl cutting allowed them to experiment with different colors and textures, resulting in a unique and professional look.

Heat Transfer

Heat transfer printing is a versatile method that allows you to create vibrant designs on sportswear. This technique involves transferring a design from a special paper onto the fabric using heat and pressure. It’s a popular choice for those looking to produce small batches of custom apparel.

Benefits

Flexibility: Heat transfer printing works well on a variety of fabrics, including cotton, polyester, and blends. You can easily switch between different materials without compromising on quality.

Vibrant Colors: The method allows for bright and vivid colors, making your designs pop. You can achieve intricate details and gradients, which are perfect for eye-catching sportswear.

Cost-Effective for Small Batches: If you’re producing a limited number of items, heat transfer printing is an economical choice. You avoid the high setup costs associated with other methods like screen printing.

Quick Turnaround: With heat transfer, you can quickly produce custom designs. This makes it ideal for last-minute orders or when you need a fast production process.

Limitations

Durability Concerns: Heat transfer prints may not be as durable as other methods. Frequent washing and wear can cause the designs to fade or peel over time.

Not Ideal for Large Orders: For bulk orders, heat transfer might not be the most efficient choice. The process can become time-consuming and costly compared to methods like screen printing.

Limited Breathability: The transfer layer can affect the fabric’s breathability. This might not be suitable for sportswear that requires high levels of comfort and ventilation.

Ideal Use Cases

Custom Team Apparel: Heat transfer is perfect for creating personalized team jerseys or workout gear. You can easily add names, numbers, or logos to your sportswear.

Promotional Items: If you’re looking to produce promotional sportswear, heat transfer offers a cost-effective solution. You can create unique designs that leave a lasting impression.

Small to Medium Orders: For smaller batches, heat transfer provides a quick and affordable option. You can produce high-quality prints without the need for large quantities.

Case Study: A local fitness club recently used heat transfer printing for their promotional t-shirts. They found that the vibrant colors and quick turnaround time helped them meet tight deadlines for an upcoming event. The flexibility of heat transfer allowed them to experiment with different designs, resulting in a unique and appealing collection of apparel.

Embroidery

Embroidery adds a touch of elegance and professionalism to sportswear. This method involves stitching designs directly onto the fabric using threads. It’s a classic choice that has stood the test of time, offering a unique texture and depth that other printing methods can’t replicate.

Benefits

Durability: Embroidery is incredibly durable. The stitched designs withstand frequent washing and wear, making them perfect for sportswear that needs to endure tough conditions. You won’t have to worry about the design fading or peeling over time.

Professional Appearance: Embroidery gives your sportswear a high-end look. The raised texture and intricate stitching add a level of sophistication that printed designs often lack. It’s an excellent choice for team uniforms or corporate sportswear.

Versatility: You can use embroidery on a wide range of fabrics, including cotton, polyester, and blends. This versatility allows you to create consistent branding across different types of apparel.

Colorfastness: The threads used in embroidery are colorfast, meaning they won’t bleed or fade easily. Your designs will maintain their vibrant colors even after multiple washes.

Limitations

Cost: Embroidery can be more expensive than other printing methods, especially for complex designs. The cost increases with the number of stitches and colors used, so it’s important to consider your budget.

Design Complexity: While embroidery excels at simple logos and text, it may not be suitable for intricate designs or detailed images. The stitching process can limit the level of detail you can achieve.

Fabric Limitations: Some fabrics, like thin or stretchy materials, may not hold up well to embroidery. The stitching can cause puckering or distortion, so it’s essential to choose the right fabric for your design.

Ideal Use Cases

Team Uniforms: Embroidery is perfect for team uniforms. You can create durable and professional-looking logos that represent your team with pride.

Corporate Sportswear: For corporate events or promotional apparel, embroidery adds a touch of class. It ensures your brand stands out with a polished and sophisticated appearance.

Caps and Jackets: Embroidery works exceptionally well on thicker fabrics like caps and jackets. The sturdy material supports the stitching, resulting in high-quality designs that last.

Case Study: A local basketball team recently opted for embroidery on their new uniforms. They found that the durability and professional appearance of the embroidered logos significantly enhanced their team’s image. The players appreciated the high-quality finish, and the uniforms held up well throughout the season, maintaining their vibrant colors and crisp designs.

When choosing the best sportswear printing methods, consider factors like order size, fabric type, and design complexity. For large orders with simple designs, screen printing offers cost-effectiveness and durability. If you need intricate designs on cotton, DTG is ideal. However, for versatility and vibrant colors across various fabrics, Direct to Film (DTF) powder printing stands out. It combines vivid colors with durability, making it a top choice for custom sportswear. A local team switched to DTF and saw enhanced vibrancy and longevity in their jerseys, proving its effectiveness. Explore our website for more on DTF powder printing.

FAQ

What type of printing methods do you offer for garments?

We offer a variety of printing methods to suit your needs. These include screen printing, digital printing, digital and vinyl transfers, and embroidery. The best method for you depends on the garment material, design complexity, and the number of items you want to print.

How do I choose the right printing method for my sportswear?

Consider the fabric type, design complexity, and order size. For large orders with simple designs, screen printing is cost-effective. If you need intricate designs on cotton, Direct-to-Garment (DTG) is ideal. For versatility and vibrant colors across various fabrics, Direct to Film (DTF) powder printing stands out.

Is DTF powder printing suitable for all types of fabrics?

Yes, DTF powder printing works well on a variety of fabrics, including cotton, polyester, and blends. This flexibility makes it a great choice for different types of sportswear, from jerseys to leggings.

What are the benefits of using embroidery for sportswear?

Embroidery offers durability and a professional appearance. It withstands frequent washing and wear, making it perfect for sportswear. The raised texture and intricate stitching add a level of sophistication that printed designs often lack.

Can I use sublimation printing on cotton fabrics?

Sublimation works best on polyester and other synthetic fabrics. If you’re working with cotton or natural fibers, consider other methods like DTG or screen printing for better results.

How does heat transfer printing compare to other methods?

Heat transfer printing is flexible and works well on various fabrics. It’s cost-effective for small batches and allows for vibrant colors. However, it may not be as durable as other methods, and the transfer layer can affect the fabric’s breathability.

What is the most durable printing method for sportswear?

Embroidery and screen printing are known for their durability. Embroidery offers long-lasting designs that withstand tough conditions, while screen printing provides vibrant colors that endure multiple washes.

Are there any limitations to using vinyl cutting for sportswear?

Vinyl cutting works best for simple designs with solid colors. It may not be suitable for intricate details or gradients. Additionally, it works best on smooth fabrics and may not adhere well to textured or stretchy materials.

How quickly can I get my custom sportswear printed?

The turnaround time depends on the printing method and order size. Methods like DTG and heat transfer offer quick production times for small orders. For larger quantities, screen printing might take longer due to setup requirements.

Why is DTF powder printing considered the best option?

DTF powder printing combines vivid colors with durability, making it a top choice for custom sportswear. It offers flexibility across various fabrics and ensures your designs pop with vibrant colors. A local team switched to DTF and saw enhanced vibrancy and longevity in their jerseys, proving its effectiveness. For more information, explore our website and discover how DTF powder printing can elevate your sportswear.