Choosing high-quality DTF powder is crucial for achieving optimal printing results, and understanding the key features of the powder is essential. The quality of DTF powder directly impacts the printing process and the durability of the final product. High-quality DTF powder ensures vibrant colors and sharp details, making it ideal for intricate designs. It plays a vital role in enhancing color saturation and fine details, resulting in impressive prints. By selecting the right DTF powder with the key features that matter, you ensure that your prints maintain their quality over time, resisting fading and wear. This choice significantly influences the overall success of your printing projects.

Key Takeaways

Choose DTF powder with uniform particle size for consistent prints; smaller particles provide a smoother finish, while larger ones can create a rough texture.

Prioritize adhesion properties to ensure your prints remain vibrant and intact over time, preventing peeling and fading after multiple washes.

Select DTF powder with the appropriate melting point to guarantee effective transfer during heat application, resulting in durable and high-quality prints.

Ensure compatibility of DTF powder with both the fabric and inks you plan to use; this enhances color saturation and detail sharpness in your designs.

Check for certifications and read customer reviews to assess the quality of DTF powder, ensuring it meets industry standards and performs well in real-world applications.

Avoid common mistakes such as overlooking particle size and neglecting compatibility checks to enhance the quality and durability of your prints.

Understanding DTF Powder

What is DTF Powder?

DTF powder, or Direct-to-Film powder, is a specialized adhesive used in the textile printing industry. This unique substance plays a crucial role in transferring patterns from a print medium, typically film, onto various fabrics. Composed of finely ground polymers, resins, and other additives, DTF powder ensures that designs adhere firmly to the fabric, resulting in vibrant and long-lasting prints. Its versatility allows it to work on a wide range of materials, including cotton, polyester, and even leather. By applying a thin layer of DTF powder on top of the printing ink, you enhance the transfer process, making it an invaluable tool for businesses engaged in custom printing.

Role of DTF Powder in Printing Process

In the DTF printing process, DTF powder serves as an essential component that facilitates the transfer of designs onto materials. Here’s how it works:

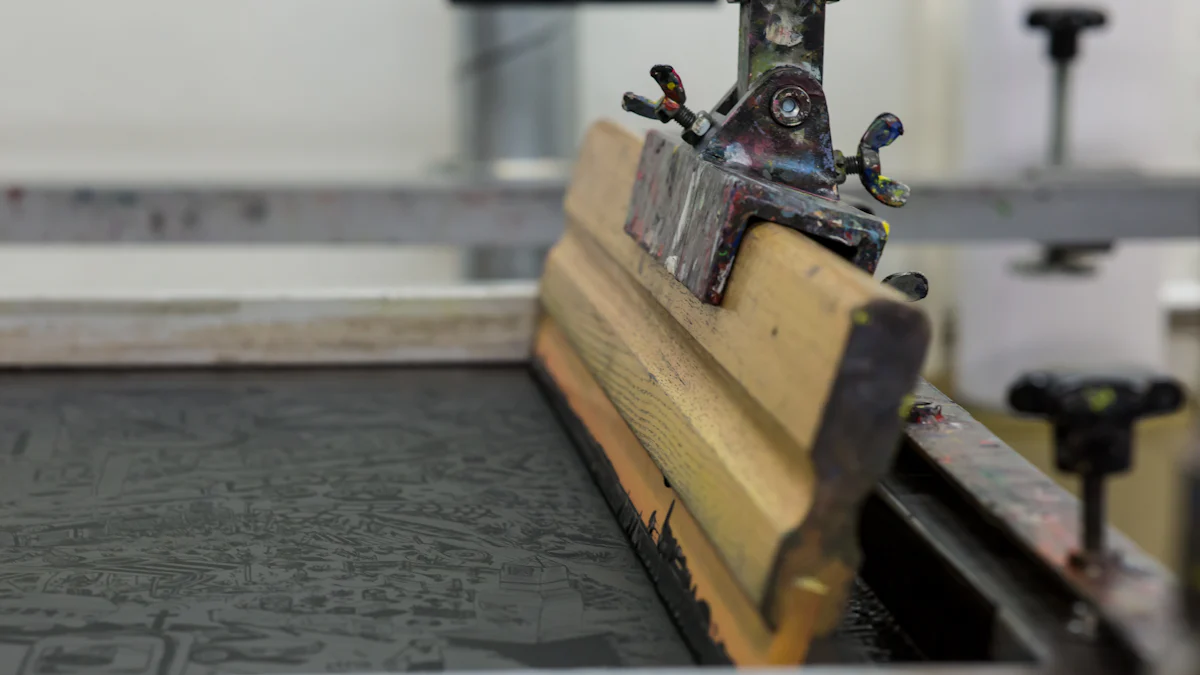

Application: After printing your design onto DTF film using quality inks, you apply the DTF powder to the wet ink. This step is crucial as the powder makes the design adhesive.

Adhesion: The powder creates a sticky layer on the printed design, ensuring that it bonds seamlessly to the fabric during the heat transfer process. This results in a durable and vibrant print with excellent adhesion.

Heat Transfer: Once you place the transfer film with the printed design and DTF powder onto the material, you apply heat. The powder melts, sticking the design onto the fabric. This method allows for high-quality prints on both light and dark textiles.

Versatility: DTF powder’s ability to adhere well to various surfaces makes it a popular choice for creating long-lasting prints. It is suitable for any fabric color, providing flexibility in design choices.

By understanding the role of DTF powder in the printing process, you can achieve impressive results with vibrant colors and sharp details. This knowledge helps you make informed decisions when selecting the right DTF powder for your printing projects, ensuring that your prints maintain their quality over time.

Key Features of High-Quality DTF Powder

Particle Size

Importance of Uniform Particle Size

When selecting DTF powder, you should pay close attention to particle size. Uniform particle size is a key feature that ensures consistency in your prints. Smaller particles, similar to flour, typically range from 0-70 microns. These fine particles provide a softer feel and a smoother finish on the fabric. In contrast, larger particles, akin to sugar, can result in a more textured and rubbery print. Consistent particle size helps maintain the quality of your prints, ensuring that each design comes out as intended.

Impact on Smooth Application

The particle size of DTF powder directly affects how smoothly it applies to the fabric. Fine particles allow for an even distribution across the design, which is crucial for achieving clear and detailed prints. This smooth application minimizes the risk of clumping or uneven coverage, which can lead to defects in the final product. By choosing a DTF powder with the right particle size, you enhance the overall appearance and feel of your prints.

Adhesion Properties

How Good Adhesion Affects Print Durability

Adhesion properties are another key feature to consider when choosing DTF powder. Good adhesion ensures that your prints remain vibrant and intact over time. The powder’s ability to bond with the fabric affects the durability of the print. Strong adhesion prevents the design from peeling or fading, even after multiple washes. This durability is essential for maintaining the quality of your prints and ensuring customer satisfaction.

Factors Influencing Adhesion Quality

Several factors influence the adhesion quality of DTF powder. The type of fabric plays a significant role; for instance, white DTF powder adheres better to synthetic fibers, while black DTF powder excels with natural fibers. The particle size also impacts adhesion, with larger particles providing stronger bonds. By understanding these factors, you can select a DTF powder that offers optimal adhesion for your specific printing needs.

Melting Point

Importance of the Right Melting Point

The melting point of DTF powder is a critical feature that affects the transfer process. A suitable melting point ensures that the powder melts evenly during heat application, allowing the design to adhere properly to the fabric. If the melting point is too high or too low, it can lead to incomplete transfers or damage to the fabric. Therefore, choosing a DTF powder with the right melting point is essential for achieving high-quality prints.

Effects on Effective Transfer

An appropriate melting point facilitates effective transfer of the design onto the fabric. When the powder melts correctly, it creates a strong bond between the ink and the material, resulting in a durable and vibrant print. This effective transfer process is vital for producing prints that withstand wear and washing. By selecting a DTF powder with the correct melting point, you ensure that your designs are transferred accurately and maintain their quality over time.

Compatibility

Compatibility with Different Fabrics

When selecting DTF powder, you must consider its compatibility with various fabrics. Different materials react differently to the powder, affecting the quality of the print. For instance, white DTF powder, with its larger particle size, adheres exceptionally well to synthetic fibers like polyester. This makes it an excellent choice for sportswear and other synthetic garments. On the other hand, black DTF powder, which consists of smaller particles, excels in adhering to natural fibers such as cotton. This distinction is crucial because it ensures that your prints maintain their vibrancy and durability across different fabric types.

To achieve the best results, you should match the DTF powder to the fabric type you are working with. This approach not only enhances the adhesion but also ensures that the prints withstand washing and wear over time. By understanding the compatibility of DTF powder with different fabrics, you can make informed decisions that lead to high-quality and long-lasting prints.

Compatibility with Various Inks

In addition to fabric compatibility, you must also consider how well the DTF powder works with different inks. The interaction between the powder and the ink plays a significant role in the final appearance of the print. Some powders may work better with specific ink formulations, affecting the color saturation and detail sharpness of the design.

For optimal results, you should test the DTF powder with the inks you plan to use. This testing helps ensure that the powder and ink combination produces vibrant colors and sharp details. By selecting a DTF powder that is compatible with your chosen inks, you enhance the overall quality of your prints and ensure customer satisfaction.

Understanding these key features of DTF powder compatibility allows you to tailor your printing process to achieve the best possible outcomes. By considering both fabric and ink compatibility, you ensure that your prints are not only visually appealing but also durable and resistant to fading.

Evaluating DTF Powder Quality

Tips for Assessing Quality

When you evaluate DTF powder quality, you ensure that your printing projects achieve the best results. Here are some practical tips to help you assess the quality of DTF powder effectively:

Checking Certifications

Certifications serve as a reliable indicator of DTF powder quality. They confirm that the product meets industry standards and regulations. When you check for certifications, you verify that the powder has undergone rigorous testing for performance and safety. Look for certifications from reputable organizations that specialize in textile printing materials. These certifications often guarantee that the powder will deliver consistent results and adhere well to fabrics.

Reading Reviews and Testimonials

Customer reviews and testimonials provide valuable insights into the performance of DTF powder. By reading these firsthand accounts, you gain a better understanding of how the powder performs in real-world applications. Pay attention to feedback regarding adhesion, color vibrancy, and durability. Positive reviews often highlight the powder’s ability to produce high-quality prints that withstand washing and wear. Conversely, negative reviews may point out issues such as poor adhesion or fading. Use this information to make informed decisions when selecting DTF powder for your projects.

By following these tips, you can confidently choose DTF powder that meets your quality standards. This careful evaluation process ensures that your prints maintain their vibrancy and durability, satisfying both you and your customers.

Common Mistakes to Avoid

When selecting DTF powder, you might encounter several pitfalls that could compromise your printing results. By being aware of these common mistakes, you can make informed decisions and achieve high-quality prints.

Overlooking Particle Size

You should never underestimate the importance of particle size in DTF powder. Many people overlook this aspect, leading to inconsistent print quality. Smaller particles provide a smoother finish and softer feel, while larger particles can result in a rougher texture. Always check the particle size to ensure it aligns with your desired print outcome. Consistency in particle size guarantees uniform application and enhances the overall appearance of your prints.

Ignoring Adhesion Properties

Adhesion properties play a crucial role in the durability of your prints. Ignoring this feature can lead to prints that peel or fade quickly. You must evaluate how well the DTF powder bonds with the fabric. Strong adhesion ensures that your designs remain vibrant and intact over time. Consider the type of fabric and the specific adhesion requirements to select a powder that provides optimal bonding.

Neglecting Compatibility Checks

Compatibility checks are essential when choosing DTF powder. Neglecting this step can result in poor print quality and wasted materials. You need to assess the compatibility of the powder with both the fabric and the inks you plan to use. Different powders work better with certain materials and ink formulations. Conduct tests to verify that the powder interacts well with your chosen fabrics and inks. This ensures that your prints maintain their vibrancy and detail, providing a professional finish.

By avoiding these common mistakes, you enhance the quality and durability of your prints. Paying attention to particle size, adhesion properties, and compatibility checks will lead to successful printing projects and satisfied customers.

Choosing high-quality DTF powder is essential for successful printing outcomes. Focus on key features like particle size, adhesion properties, melting point, and compatibility with fabrics and inks. These elements ensure vibrant, durable prints that withstand wear and washing. Proper storage and handling of DTF powder also play a crucial role in maintaining print quality. By applying these tips, you make informed purchasing decisions that enhance your printing projects. Remember, the right DTF powder can revolutionize your custom apparel creations, offering versatility and efficiency.

FAQ

What is the significance of choosing high-quality DTF powder?

Selecting high-quality DTF powder is crucial for achieving vibrant and durable prints. It ensures excellent adhesion, which prevents designs from peeling or fading over time. High-quality powder also enhances color saturation and detail sharpness, making your prints stand out.

How does particle size affect DTF printing?

Particle size plays a vital role in the quality of your prints. Smaller particles provide a smoother finish and softer feel, while larger particles can create a rougher texture. Consistent particle size ensures uniform application, leading to high-quality prints.

Why is adhesion important in DTF powder?

Adhesion properties determine how well the design bonds with the fabric. Good adhesion ensures that prints remain vibrant and intact, even after multiple washes. This durability is essential for maintaining print quality and customer satisfaction.

What should I consider regarding the melting point of DTF powder?

The melting point affects the transfer process. A suitable melting point ensures that the powder melts evenly during heat application, allowing the design to adhere properly to the fabric. Choosing the right melting point is essential for achieving high-quality prints.

How do I evaluate the quality of DTF powder?

To assess DTF powder quality, check for certifications that confirm the product meets industry standards. Reading reviews and testimonials also provides insights into the powder’s performance in real-world applications. These steps help ensure you select a high-quality product.

Can DTF powder be used on all types of fabrics?

DTF powder is versatile and can adhere to various fabrics, including cotton, polyester, and leather. However, compatibility varies, so it’s important to match the powder to the fabric type for optimal results. This ensures that prints maintain their vibrancy and durability.

How does DTF powder interact with different inks?

The interaction between DTF powder and inks affects the final appearance of the print. Some powders work better with specific ink formulations, impacting color saturation and detail sharpness. Testing the powder with your chosen inks ensures optimal print quality.

What are common mistakes to avoid when selecting DTF powder?

Avoid overlooking particle size, ignoring adhesion properties, and neglecting compatibility checks. These factors significantly impact print quality. Paying attention to these aspects ensures successful printing projects and satisfied customers.

How can I ensure my DTF prints are durable?

To ensure durability, choose a DTF powder with strong adhesion properties and the right melting point. Proper storage and handling of the powder also play a crucial role in maintaining print quality. These practices help your prints withstand wear and washing.

Is investing in quality equipment important for DTF printing?

Yes, investing in quality equipment, such as a high-quality heat press, can lead to exceptional outcomes in the DTF process. Quality equipment ensures consistent high-quality printing results, enhancing the overall success of your printing projects.